Shop Drawing Services in Maine

Building a home in Maine can cost over $175 per square foot. Get the drawings right, and you save time, money, and headaches. At CAD Drafters, our shop drawing services in Maine translate architectural plans into fabrication-ready notes that detect issues early, speed permit approvals, and eliminate costly change order needs. Hire us to experience the difference we can make!

Healthcare Facilities

Commercial Complexes

Educational Institutions

Manufacturing Plants

Residential Developments

Hospitality & Retail Spaces

Why Our Shop Drawing Expertise Stands Out?

You don’t need to give space to an in-house team for shop drawings; we outsource services, enabling you to save on in-house drafters’ expenses. No need to worry about details, availability hours, delivery time, etc, we outstand other shop drawing companies when it comes to our working qualities.

24/7 Customer Support

We are available 24/7, providing reliable shop drawing services in Maine. Our round-the-clock coordination supports permitting questions, fabrication hold points, and on-the-fly markups. We log requests with response SLAs, escalate complex conflicts to our senior drafter, and provide timely replies. That constant coverage reduces downtime, keeps deliveries on track, and protects your contract dates and minimizes costly project delays.

Revisions With No Limits

Iteration on illustration is how accurate shop drawings happen. We don’t charge for changes and revise until the model, MEP routing, and connection details align with site specifications. Unlimited revision cycles for approved scopes mean contractors avoid surprises on-site. Our CO plans, delta-markups, and version control keep everyone on the same page, an effective approach to avoid rework and save time and money.

Affordable Service Charges

Whatever the trade you need shop drawings for, we will provide excellent outcomes, tailored to the unique features of your project, all at highly affordable service charges. Your budget will never slip, and your bank will remain healthy when you hire us for shop drawing services in Maine. You will also have a custom package option that suits your needs. Call us and share what is fit for you!

Need permit-ready, fabrication-ready sets? Request a quote now!

Professional Shop Drawings Across All CSI Trades

We deal with every CSI division, from concrete and structural steel to MEP, fire protection, interiors, and finishes, producing tailored shop drawings that match each trade’s local standards. Leveraging the expertise of certified engineers, drafters, and trade-specific reviewers, we ensure to validate connections, load paths, clearances, and splice details.

Furthermore, using project templates and live coordination platforms, we cross-check takeoffs and buyout lists so quantities align with procurement. This approach is integral in our outsourced shop drawing services, reducing RFIs, speeding up submissions, and lowering fabrication rejectsAs one of the experienced shop drawing companies in the state, we hit accuracy, track revisions, and report errors. These all struggles are made so you can get audit reports, stamped sheets, and fabrication-ready sets, whcih ultimately streamlines construction planning while helping you stay within budget and deadline. Check out our range of services below!

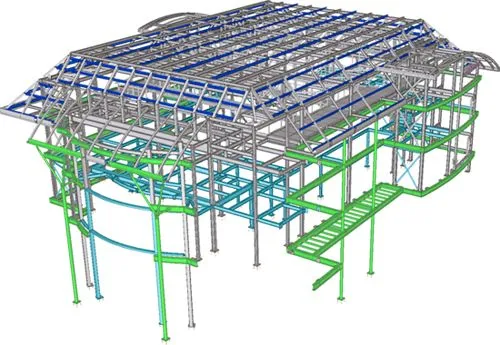

Steel Shop Drawing Services

Our steel shop drawings include comprehensive connection details, bolt patterns, camber and splice layouts, and plate geometry for fabricators. You will get CNC-ready markups, erection sequencing, and member labeling tied to the model. You can also ask for stamped shop sheets; we provide these for code compliance.

Electrical Shop Drawing Services

Hire us for electrical shop drawing services and get details on power risers, panel schedules, conduit runs, load calculations, and coordination with lighting and fire alarm systems. We verify capacity, feeder sizing, and device locations against architectural constraints. Deliverables include CAD and BIM-ready schematics with conduit fill.

Mechanical Shop Drawing Services

This includes notes on HVAC layouts, ductwork routing, equipment schedules, and coordination with the structure. We model static pressure, clearances, equipment pads, and access requirements. Final reports include fabrication dimensions, splice details, and BIM overlays for clash detection and coordination reviews.

Pipe Spool Shop Drawing Services

Our pipe spool shop drawing services are famous in Maine. We provide precise drawings with welded and grooved joint details, ISO spools, bend geometry, and fabrication notes. Our team also includes welding symbols, material specifications, cutting lists, and CNC annotations. Regarding deliverables, they include fabrication-ready DWG/DXF files with spool IDs and BOM.

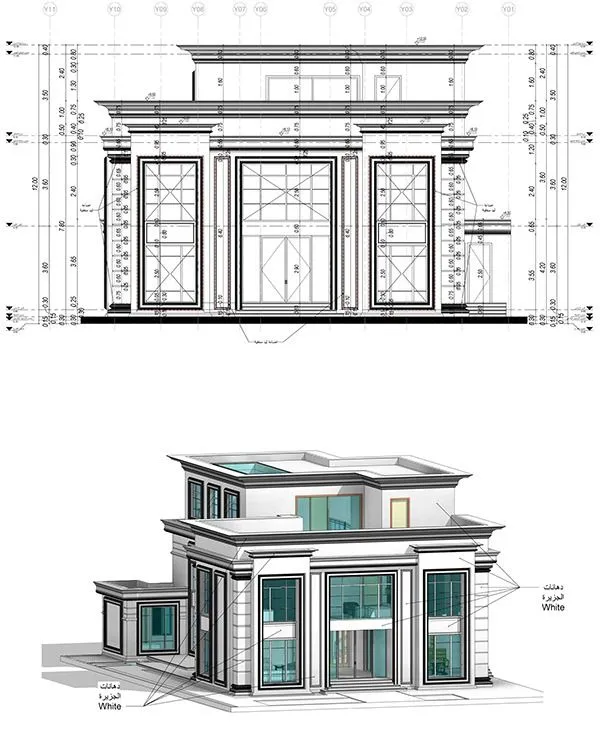

Facade Shop Drawing Services

Our facade shop drawings show data on curtainwall elevations, mullion schedules, glazing patterns, anchorage details, and thermal break specifications. We validate wind loads, attachment tolerances, and interface with structure and waterproofing. Deliverables include fabrication layouts, glass schedules, and shop coordinates for on-site, smooth installation.

Millwork Shop Drawing Services

Casework elevations, joinery details, CNC files, and finish schedules tailored to interior elevations. We provide material callouts, hardware sets, installation sequences, and factory QA checklists to ensure fit and finish before shipment and site installation checks.

MEP Shop Drawing Services

Hire us for MEP shop drawing services and get data on integrated electrical, mechanical, and plumbing models. Our reports will help you resolve clashes and coordinate shared specifications. We rely on combined services schematics, routing plans, penetrations, and utility tie-ins to provide you with the best plans. Deliverables include prefabrication notes, material lists, and procurement plans, reducing onsite coordination issues.

Fabrication Shop Drawing Services

This includes shop-ready production drawings for metalwork, ductwork, wood assemblies, and specialty fabrications. We add CNC annotations, tolerance notes, weld symbols, and assembly sequences in the plans. Final results include cutting lists and vendor-ready drawings that speed the project cycle and reduce waste.

Precast Shop Drawing Services

The assessment shows details on panel layouts, project schedules, lifting diagrams, and erection sequences aligned with structural plans. We coordinate camber, connection plates, sealant joints, bolt patterns, and shop marks to produce erection sheets that align with crane plans and delivery sequencing.

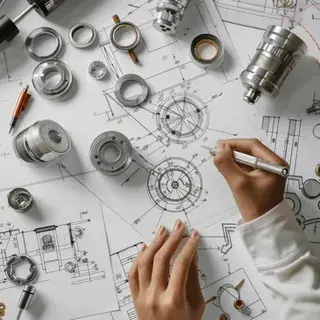

Methods We Use to Deliver Highly Accurate Shop Drawing Services in Maine

Our structured shop drawing services in Maine, powered by advanced tools and an accuracy-focused process, reduce clashes and rework needs. From coordinated models to material verification and layered deliverables, we prioritize consistency, traceability, which leads to fewer financial surprises at fabrication and on-site.

Advanced Drafting Tools

We use BIM and CAD platforms to automate clash detection and CNC export plugins feed fabrication. This ensures you receive transparent models, sheet sets, and annotated exports that reduce translation errors and speed up procurement and construction.

Strict QA Reviews

At CAD Drafters, every drawing undergoes model validation, dimensional audits, and cross-discipline sign-off. We run structural integrity tests, verify penetrations and bolt patterns, document corrections, and publish QA reports with issues and root causes. This way, we enable you to fix systemic problems quickly.

Error-Free Workflow

Our proven QC strategies stop errors early, whether with model freeze points, pre-fab sign-offs, or final verification. Furthermore, our automated reports help determine unresolved clashes, such as change logs provide traceability. Simply put, this workflow shortens project duration and reduces rejection chances.

Material Verification

We cross-check specifications and final documents against shop details to prevent mismatches. Our deep-rooted process confirms finishes, gauges, and proprietary items before fabrication. As verification ties to purchase orders, vendors fabricate to confirmed specifications, cutting rework and project delivery delays.

Clear Layer Detailing

During shop drawing services in Maine, we enforce naming conventions, layers, and color-coded annotations, enabling you to read drawings without issues. Our layering reports include fabrication, field installation, tolerances, and inspection notes, and we help you with clear layering that reduces translation errors when exporting to CNC and nesting software.

Seamless Team Coordination

At our shop drawing company, a dedicated coordinator runs weekly calls, issues model deltas, and tracks action items. That single contact reduces RFIs, eliminates duplicated effort, and keeps all trades aligned on one version-controlled model. This makes fabrication and procurement perfect.

Fully Code-Compliant Shop Drawing Services Across Maine

Code compliance avoids costly rework, failed inspections, and approval delays. Our shop drawings in construction follow local building codes, fire safety, energy, and accessibility requirements, so permits and AHJ reviews pass in one go. We cross-reference code sections, include stamped calculations, and produce documentation for inspections. Our approach to staying code-aligned reduces hold-ups, speeds closeout, and keeps owners away from liability through the design and drafting process.

Here are the building codes we consider during technical drawings

- ASTM Standards

- UL: Underwriters Laboratories standards

- ACI 318: Building Code Requirements for Structural Concrete

- NFPA 70: National Electrical Code (NEC)

- NFPA 101: Life Safety Code

- IBC: International Building Code

- IRC: International Residential Code

- 1ASCE 7: Minimum Design Loads for Buildings and Other Structures

- AISC: Steel Construction Manual / American Institute of Steel Construction standards

- AWS: American Welding Society codes (D1.1 for structural welding)

Our Transparent Construction Shop Drawing Process

At CAD Drafters, we use cloud platforms, shared models, and live updates so everyone gets the same information. Our issue tracking, version control, and model handling keep changes auditable. Furthermore, clients access dashboards and download packages anytime, improving coordination between architects, contractors, and fabricators. Simply put, quality is utmost when you hire us for shop drawing services in Maine. Check out our process below.

Initial Data Analysis

Our team starts with benchmarking timelines, reviewing contract documents, and importing models for clash detection. This ensures effective sequencing plans, structural integrity, and streamlined procurement. Furthermore, our initial assessment determines 90% of the issues in the plans, enabling cut conflicts, reducing downtimes, and fewer COs. Hence, you receive estimates-ready drawings, ready for approval without rework headaches.

Detailed Drafting & Coordination

Next, our shop drawing team works on a sheet with LOD 400 details, MEP coordination, and labeled sequencing plans. Each set of drawings shows comprehensive data, including BOMs, specifying details, and CNC-ready exportable files. Regular clash detection is run to avoid project coordination issues and meet the deadline. This ultimately speeds up fabrication while keeping rework needs as low as possible.

Final QA & Delivery

At CAD Drafters, we have a 100-point checklist that we use before the submission of final drawings. This way, we verify dimensional data and ensure annotation consistency. Then, stamped PDFs and models are exported with revisions, CNC files, and erection notes. Hence, our final step, QA, eliminates the chances of rejection while ensuring febricators have executable plans.

Why Working With Our Shop Drawing Team?

Our shop drawing team blends 2+ decades of field experience and technical experts, including engineers, certified BIM coordinators, fabricators, and senior drafters. Furthermore, we hold industry certifications for meeting deadlines and fostering smooth communication across all construction projects. Additionally, our combination of practical trade knowledge and digital expertise leads to fewer financial surprises, faster approvals, and better outcomes. The following are our more unique qualities.

Ongoing Support

We provide 24/7 support with ongoing assistance so you keep your project on track from the first to the last shot. Unlimited revisions are provided, and on-site coordination is continued so you can complete your project with the highest possible standards.

100% Customer Satisfaction

Our quality metrics and client surveys benchmark performance. As one of the leading shop drawing companies, we measure your satisfaction, track SLAs, and resolve issues until you confirm acceptance.

High Affordability

Unlike other firms, we consider your spending range and provide the best construction shop drawings at highly affordable service charges. Hence, you receive more and spend less, directly increasing your revenue.

The Best Shop Drawing Services in Maine

Choosing our shop drawing experts means immediate, measurable benefits across preconstruction and delivery. We routinely see an 85% improvement in internal drawing workflows, supported by fewer handoffs, accurate modelling, and faster approvals.

Clients report an 8–15% profit margin increase from reduced rework and better takeoffs. Similarly, a 98% bid-success correlation is experienced when our technical drawings are coordinated early, and an average 20% business growth is tied to faster project completion. Furthermore, accuracy rates are high: first-pass acceptance commonly exceeds 95%, and fabrication rejects drop below 3%.

Beyond stats, you get no schedule issues, transparent procurement plans, and repeatable quality that helps you win more work. Our experts provide shop drawing services in Maine, pair local codes with cloud-based delivery, ensuring material verification and seamless project coordination.

Hire us to explore all the benefits our services bring!

Clients’ Reviews

FAQs

How do your construction shop drawings keep the budget updated and tight?

We create precise and accurate drawings that highlight issues early. Once we have problem details, we help you create a mitigation plan to avoid budget overruns during construction.

What file formats do you deliver the final shop drawings in?

We prefer DWG, DXF, PDF, and BIM exports.

How long does it take to create a construction shop drawing for an office project?

At CAD Drafters, we take 24-72 hours only.

Do you keep client drawings and project information confidential?

No compromise on that; we use secure cloud storage, role-based access, NDA protocols, and encrypted file transfer, ensuring your data is in safe hands.