Accuracy matters in the construction industry. It matters at every stage of every project, from the first time you submit a bid to your last project closeout. Even minor mistakes made during measurement and estimation can lead to cost overruns, delays, and even disputes. That’s where construction takeoffs come in. A construction takeoff is critical because it gives contractors, builders, and project managers a clear view of the materials, quantities, and resources they need for a project, allowing them to establish budgets, plan their work, and coordinate effectively.

This article will define what construction takeoffs are, describe the different types, outline the process and steps involved in takeoffs, identify the tools used to create takeoffs, and highlight why it is important that takeoffs are accurate. We will identify some common mistakes to avoid and how takeoffs fit into the ai construction lifecycle, as well as provide a FAQ section to answer common questions.

What is a Construction Takeoff?

A construction takeoff (also called material takeoff or quantity takeoff) involves finding and measuring all materials for a construction project. Essentially, the purpose of a takeoff is to quantify what is needed (concrete, lumber, steel, flooring, drywall, piping, wiring, etc.) to prepare a cost estimate and schedule.

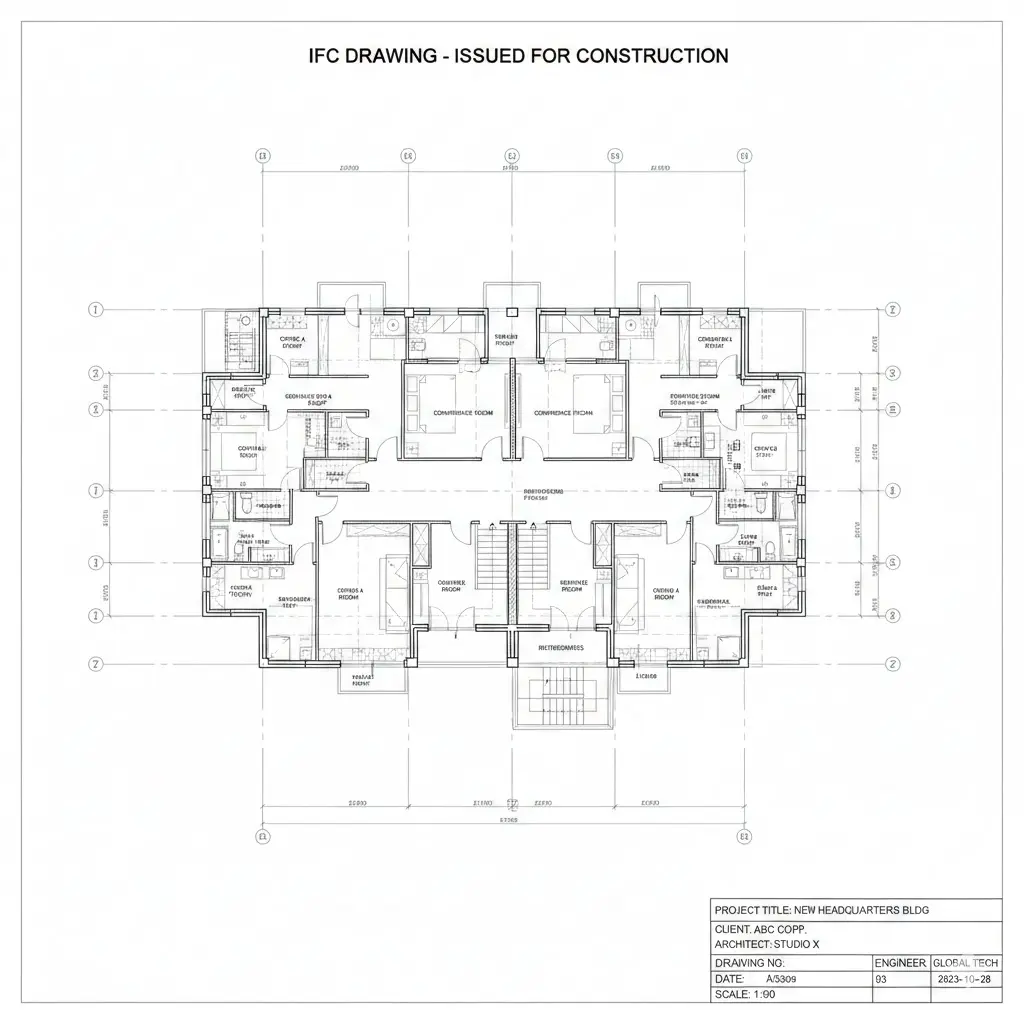

Takeoffs do not simply count raw materials, but will often include the details (size, type, specification, etc.) of every item. For example, a takeoff will more likely specify “250 linear feet of 2×4 pressure-treated lumber” as opposed to simply “lumber”. The term “takeoff” comes from the idea of “taking off” quantities from drawings/plans. Today, with the advent of digital blueprints, the takeoff is being accomplished from electronic plans, but the concept is the same.

In summary, a construction takeoff constitutes the groundwork of cost estimating and the procurement process. Without a takeoff, contractors cannot complete accurate bids, and project owners cannot reliably budget for their project.

Types of Construction Takeoffs

At a high level, construction takeoffs fall into two categories, manual takeoffs (the traditional way) and digital takeoffs.

Manual Takeoffs

A manual takeoff uses paper blueprints as the basis for estimating the required quantities of materials for a project. Estimators will use a ruler, highlighter, and calculator to record the quantities on an Excel spreadsheet or in notebooks. The manual process can be an accurate way of estimating as long as you are diligent, but seriously, it is a slow process and error-prone.

Digital Takeoffs

Today, the process of estimating has been made easier with construction software, and digital takeoffs have become the new standard for estimating. Estimators are able to use digital blueprints and specialised software to obtain measurements of areas, lengths, and volumes directly from their screens. These estimating software programs will calculate the quantities and allow estimators to upload to their cost estimating software and produce estimates much quicker and dependably.

Material vs. Labour Takeoffs

The other way takeoffs can be categorised is based on what is being measured:

Material Takeoffs – the direct focus is on estimating the material takeoffs, such as bricks, steel, or glass.

Labour Takeoffs – focused on estimating the labour hours using the scope and scale of work.

Combined Takeoffs – includes both the material and labour to provide a total view.

While a given project may not need all the types, it is typical that projects would have some combination of material and labour takeoffs.

Stages in the Construction Takeoff

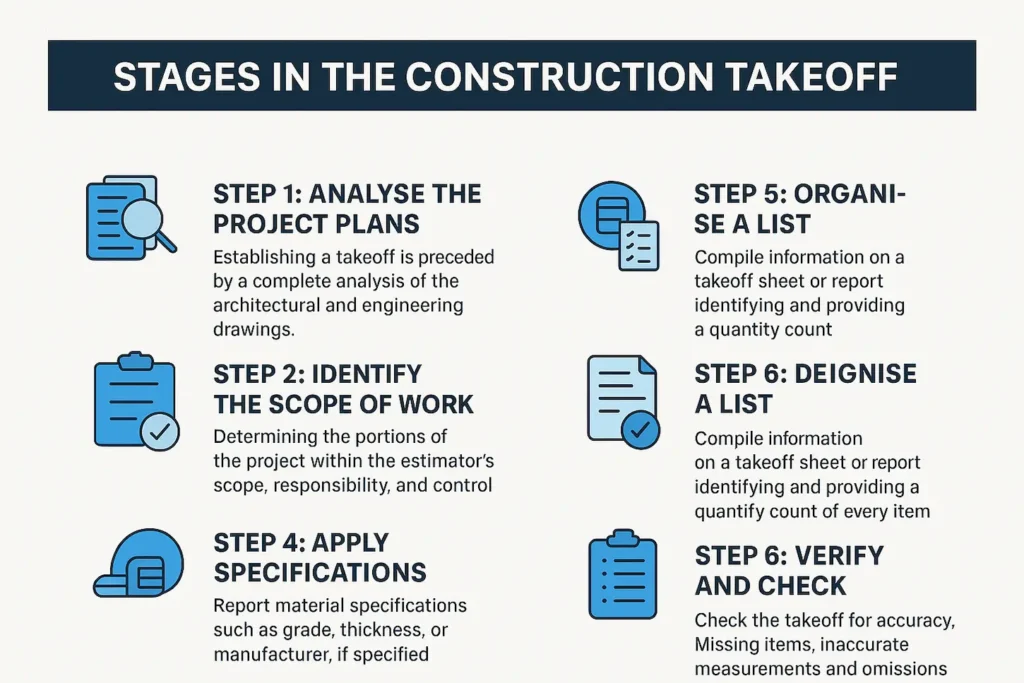

As you can see, there are many steps in the takeoff process:

Step 1: Analyse the Project Plans

Establishing a takeoff is preceded by a complete analysis of the architectural and engineering drawings. This analysis includes knowledge of any notes, specifications, or revisions that pertain to the quantities.

Step 2: Identify the Scope of Work

The next step is determining what portions of the project will be in the scope, responsibility, and control of the estimator. For example, a subcontractor doing electrical work will only be estimating those quantities, not everything needed to get the unit completed.e

Step 3: Take Measurements

Estimators measure the length, area, volume, and counts through traditional means of measuring or by utilising software technologies. For example, estimating the cubic yards of concrete needed for a foundation or how many square feet of roofing material will be required.

Step 4: Apply Specifications

Not all materials are the same. Estimators should also report specifications such as grade, thickness, or the manufacturer’s name if specified in the project documentation.

Step 5: Organise a List

After that, the information is compiled on a takeoff sheet or report; this report identifies and provides a quantity count of every item. This report also typically provides unit of measure (linear feet, square feet, cubic yards, etc.).

Step 6: Verify and Check

Finally, the takeoff will be checked for accuracy. Missing items, inaccurate measurements and omissions can lead to big discrepancies in cost. Many companies have a peer review process, where the takeoff would be reviewed by another estimator.

Tired of slow manual takeoffs? Our team uses industry-leading digital software to deliver faster, more accurate results.

Contact UsTools and Software for Construction Takeoffs

Modern technology has changed the way takeoffs are completed. Some of the most common tools include:

Bluebeam Revu – This software is used by many to “mark up” and measure computer-drawn designs in PDF.

PlanSwift – This software allows the user to drag and drop measurements where needed and Count Materials quickly.

Stack – A cloud-based takeoff software developed to allow teams to work together.

On-Screen Takeoff (OST) – A digital method that has been around for a long time. i.e. It works with estimating programs.

Trimble and Autodesk Tools – These tools are often used by larger firms to do advanced digital takeoffs connected to Building Information Modelling (BIM).

These tools save time, minimise human error, and allow for real-time work between estimators, project managers, and subcontractors.

Accountability through Accurate Construction Takeoffs

Accurate construction takeoffs offer meaningful benefits throughout a project’s lifecycle. They are the linchpin for reliable costs associated with the project, which in turn provides competitive, yet still profitable bids, rather than cheap or inflated ones. When all quantities are clearly assessed, creation of a project procurement will be more efficient, allowing corresponding quantities that contractors had anticipated in their bids, and preventing a contractor from running out of material or stockpiling excess. Because they can avoid purchases, takeoffs will aid in avoiding waste through unnecessary purchases and allow contractors to create a more sustainable regulated practice/process.

Accurate takeoffs save procuring time on site, allowing contractor crews to concentrate on construction rather than introducing more complications from missing supplies or wasted project time. Accurate takeoffs provide more clarity on site labour and material, which also allows scheduling and coordination to be planned and smooth and flow with precision. Overall, they provide more accuracy, building owner trust, since Owners are more trusting of contractors because attention is on detail from the beginning, as opposed to simply rushing to put together a rush bid that will be overpriced or not real in the first place.

Blunders to Avoid On Takeoffs

Many blunders can take the accuracy out of construction takeoffs. The most common issue here is failing to observe something in the project plans, à la, a minor fixture or finish, and in turn, receiving an incomplete estimate. Every detail matters, and it’s usually only minor things that yield more cost and schedule impacts – not the big items.

A second blunder occurs when measurements are hastily taken or performed without a secondary check that will produce inaccurate quantities. If measuring to the edge of a room is hastily taken, that mistake will throw the whole takeoff off. The next mistake is using old-based drawings. And even if the plans are current, changes to design or scope sometimes don’t reflect perfect accuracy, leading to differences in the takeoff compared to the actual project or work.

Other measurements are missed when team member contributions sometimes lead to units of measure that are inconsistent with the overall takeoff. Not adding in waste factors, variations in materials, or site conditions can lead to missing quantities in the takeoff. Yes, performance can be affected, but budgets can be greatly affected as well. And the cost of losing time can delay procurement and subsequently construction.

How Takeoffs Fit into the Construction Project Lifecycle

It is important to understand that construction takeoffs are not simply a single task—they are inherently interlaced along the entire project lifecycle.

From Bidding to Completion of Construction

Takeoffs most typically occur in the bidding phase of the project—this is when contractors will take off quantities to establish how much material will be necessary to formulate a cost estimate. If the bid is subsequently awarded to that contractor, the same information will be used during procurement and scheduling, as well as for budgeting. During construction, the takeoff may require adjustments or changes because of a change in the design, existing site conditions, or a change in the scope.

Coordination with Estimators, Project Managers and Suppliers

Takeoffs connect these roles:

- Estimators reference takeoffs to build their bids accurately.

- Project Managers reference takeoffs to track their budgets and progress on the stated scopes of work.

- Suppliers reference takeoffs to ensure their orders are correct and include what is requested.

Thus, the takeoff is more than a list of numbers; the takeoff is a communication tool for the project team.

Final Thoughts

Construction takeoffs are the foundation of every successful project. They supply the necessary quantities and information needed for estimating, procurement, and building to proceed smoothly. Even if we rely on software to prepare a takeoff, the accuracy of the takeoff is key to the financial success of the entire project.

By understanding how the process works, understanding the common pitfalls of estimating takeoffs, and knowing how to effectively integrate takeoffs into the project life-cycle, construction professionals will ensure better outcomes for themselves and their clients.

Construction Takeoff: FAQs

A construction takeoff is looking at the drawings and accurately measuring out all the materials and quantities that will be needed for a project in order to get accurate costs/procurement plans.

Not quite. A takeoff is simply measuring quantities, while an estimate applies predetermined prices, labour costs, and overhead to those quantities to calculate total project costs.

Common tools for takeoffs are: Bluebeam Revu, PlanSwift, Stack, On-Screen Takeoff, and anything associated with Autodesk.

A takeoff will allow for accurate budgeting, waste to be reduced, purchases to be made efficiently, and overall project planning diligence.

Certainly, takeoffs can be done manually, but using software improves the speed, accuracy, and ease of updating.

Takeoffs should be updated whenever design changes, scope changes, or new information becomes available in order to have accuracy in the planning of a project.