To everyone involved in construction and engineering, drawings are not just images; they are the basis of a project. They provide clarity, direction, and a shared language for architects, engineers, contractors, and clients to follow. Drawings take on many different forms in construction, and many people confuse design drawings with shop drawings. Both design drawings and shop drawings are important drawings, but they come from different locations and have different implications.

This article will explain design drawings and shop drawings—what they are, how they are different, and what is important to know for construction project success.

What are Design Drawings?

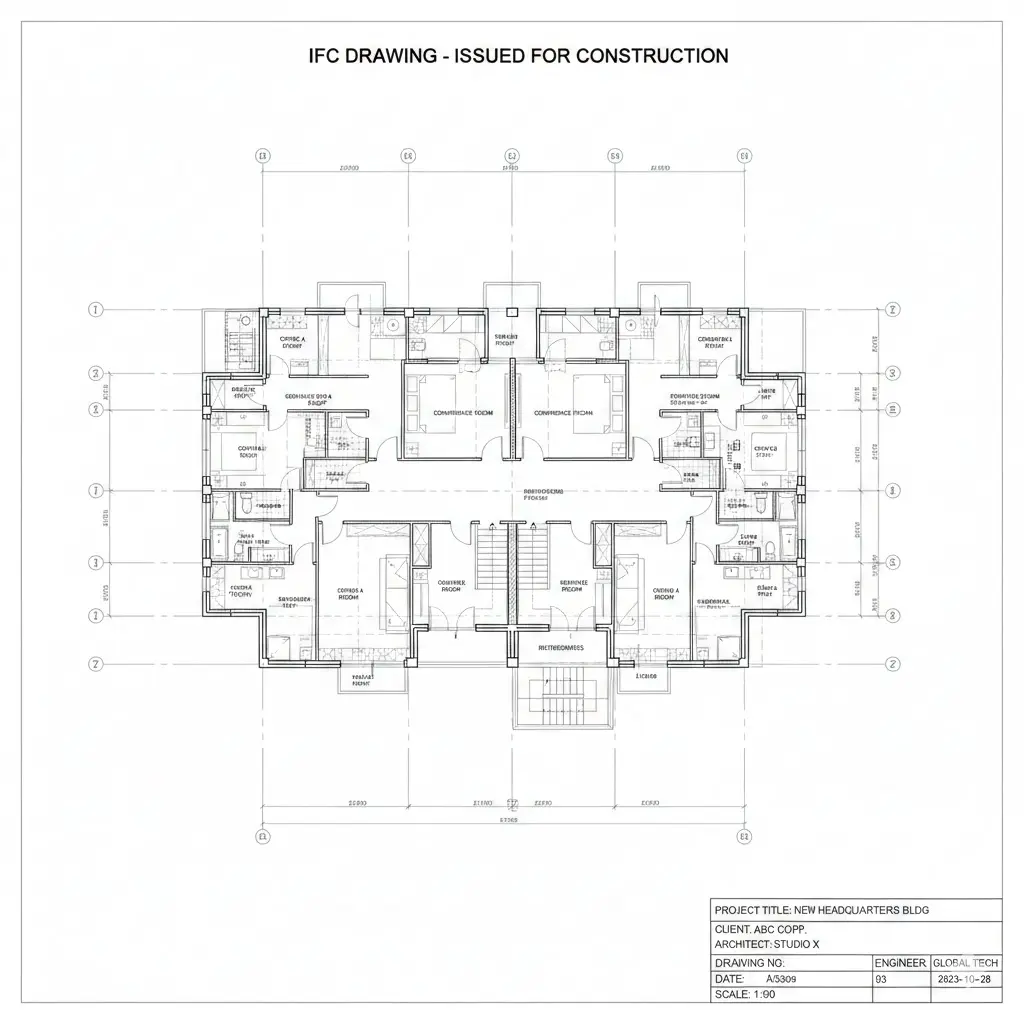

Design drawings are prepared in the early parts of a project by architects and engineers to relay the conceptual intent, concept, and framework of a project. They serve as a visual overview of how the finished structure is intended to look and function.

Design drawings usually include floor plans, elevations, and sections that depict the form, size, and spatial organisation of a building. Design drawings will define the materials, finishes, and performance requirements, but they will not include the level of complexity necessary for manufacture or installation.

The design drawing’s role goes beyond communicating within the construction team. Design drawings can also be used to convey ideas to clients, obtain approvals from regulatory agencies, and demonstrate that the project complies with current codes and standards. And they are also the basis for detailed technical drawings.

What are Shop Drawings?

While design drawings illustrate intent, shop drawings take that intent and develop it into definitive technical information. Shop drawings are created by contractors, fabricators, subcontractors, or CAD drafters, and they are comprised of the exact information to obtain for manufacture and installation.

Shop drawings have dimensions and material and fabrication methods, connection details, assembly information and installation solutions. Shop drawings do not imply new designs; they do take the architect’s ideas and interpretation and turn them into practical and constructable ideas.

Some examples of shop drawings are mechanical and electrical layouts, details for custom millwork, diagrams for steel fabrication, plumbing drawings, and drawings that give notations and specifications. These drawings contain a lot of detail and potentially include every bolt, joint, and fixture so that what is eventually fabricated is compliant with the designers’ intentions.

The importance of shop drawings cannot be understated

Accuracy for fabrication and installation: Shop drawings provide detailed instructions that improve the accuracy of production and assembly by minimising defects.

Clash detection: Shop drawings can help to identify potential clashes between systems. For example, ductwork may possibly clash with structural beams during the construction process or in any emergencies.

Efficiency gains in time and cost: In the drawing phase, some conflicts or issues can be resolved well before construction begins, which leads to more efficient construction and less costly rework.

Compliance: Shop drawings are reviewed and approved by the Architect/Engineer (A/E) prior to fabrication and installation, and there are checks to ensure the drawings comply with design intent and regulatory requirements.

From Design Drawings to Shop Drawings

The process of translating design drawings into shop drawings is a team-driven process that is systematic and organised from its inception. Contractors and/or drafting professionals utilise the design documents in recipients’ noticing them, to create shop drawings that outline exact dimensions, construction methods and materials.

Shop drawings are coordinated with the other trades to avoid problems or conflicts. For instance, the electrical will have to be coordinated with the plumbing or mechanical so that they do not interfere with each other. Once drafted, the shop drawings are submitted to regular architects and engineers for review and approval. The intent and technical aspects of the understanding of the design drawings will ensure that they intersect with regard to the review and approval process.

Only after approval can the shop drawings be used as a basis for fabrication and installation; they are the last step separating conceptual planning from site realisation.

Main Differences Between Design Drawings and Shop Drawings

Design drawings and shop drawings serve different purposes as a whole, but both are extremely important. Design drawings are conceptual in nature and focus on the overall vision of the project while ensuring compliance with regulatory authorities. Shop drawings are focused on the technicality of the project, which relates to execution and how to accurately and efficiently build the project.

Design drawings tend to be higher-level and, thus, less detailed than shop drawings, which provide all the information needed by the manufacturer to fabricate the item. Design drawings are intended for clients, designers and regulatory authorities, while shop drawings are directed to the people who will manufacture, assemble and install the work. Together, design drawings and shop drawings will ensure that the project is aesthetically fulfilling the vision and also technically workable in the field while under construction.

The Importance of Both in Construction Projects

Both types of drawings are equally important. Design drawings establish the initial framework and interpretation for the project, providing an initial motive and helping all stakeholders understand the same vision of the outcome. Shop drawings take that vision and make it applicable for construction purposes, thus reducing ambiguity and ensuring a smoother execution on site.

Get In Touch With Us Today For More Details

Contact UsUltimately, they both serve to enhance communication, mitigate errors, improve project timing and stay consistent with the client’s expectations. A project that adheres to just design drawings lacks the technical clarity needed to produce a part that has been fabricated, and a project using just shop drawings would lack the clarity of a conceptual vision and adherence.

How Design Drawings and Shop Drawings Work Together

Design drawings and shop drawings are not stand-alone documents, but two pieces of the same process. Designers use design drawings to provide direction, while contractors will use shop drawings to respond in a technical manner. The architect’s approval of shop drawings retains the integrity of the original vision and provides a working document, with the potential for variations based on the realities of construction.

To be effective, designers and builders need to collaborate as they are interrelated professions. Prompt communication practices reduce confusion and improve efficiencies in the leadership role, and if miscommunication occurs, they have the potential to limit potential design quality. Ultimately, design drawings and shop drawings can be seen as partners in completing the construction cycle; they develop interdependently.

The Role of CAD Drafters in Shop Drawings

CAD technology is central to producing accurate and flexible shop drawings in the modern industry. CAD drafters have the vital role of creating in-depth digital models, utilising three-dimensional views, and leveraging building information modelling (BIM) to coordinate work and find clashes.

The CAD drafters’ process creates more accuracy, less revision time, and improved coordination between various groups. By utilising technology, the CAD drafters turn the conceptual intent of the design into acceptable documents published for action, integrating them in the construction process.

Misconceptions Regarding Design Drawings and Shop Drawings

There are many misconceptions regarding these drawings. One misconception is that shop drawings are simply further developed and more detailed design drawings. These two documents serve different purposes. Design drawings convey intent; shop drawings convey how intent gets made.

Another misconception is that shop drawings are only for larger-scale projects. The truth is, even small custom projects (e.g., furniture, millwork, or residential systems) utilise shop drawings as a means of accuracy. A third misconception is the belief that highly detailed and developed design drawings would negate any reason to have shop drawings. Experience has shown that neglecting shop drawings will probably result in costly errors and disagreements.

Real World Example of Design versus Shop Drawings within a Project

To further emphasise the difference, let’s take the example of a commercial office tower. The architect’s design drawings could indicate the general locations of the HVAC systems, electrical risers, and plumbing lines; essentially, the drawings inform the intent; however provide no dimensions or connection details required to install the equipment, duct, electrical or pipe runs.

When the mechanical contractor provides the shop drawings, they will show sizes of ducts, connections, hanger locations, etc. Likewise, the electrical contractor will present a detailed location of the conduits planned to be installed. During pre-construction coordination, a potential conflict may be discovered, and that is that the ductwork is planned to be installed in the same ceiling space that the electrical riser occupies.

With all of that detailed information, shop drawings allow the owner to discover conflicts and resolve them before going to the site. This example illustrates how shop drawings allow for the protection of costs and time by discovering and solving problems before any work commences on site.

How Outsourcing Shop Drawings Enhances Accuracy

Shop drawings are increasingly being outsourced, with many advantages. Drafting is a speciality that can be done by a firm or freelance professionals who are higher-skilled, more efficient and objective.

Outsourcing shop drawings takes the burden off in-house drafting personnel, reduces costs for requirements for some software and training, and saves time to complete drawings. From experience, shop drawings increase the likelihood of finding conflicts or items that would be missed due to fatigue or working later in the design phase, simply because shop drawing professionals frequently venture outside their trusted primary dust, so to speak, in order to provide a fresh look to projects to identify potential conflicts. Forcing internal teams to cut corners and suffer errors is not the recommended consider the resolution of drawing conflicts to ensure project reliability and accuracy when they could otherwise be avoided.

Conclusion

On the surface, design drawings and shop drawings are clearly different items in construction documentation. Design drawings communicate vision, intent and compliance; shop drawings deliver the exact technical detail necessary to execute the vision. One defines what is to be built, while the other explains how to build it.

Both documents provide clarity and discipline in delivering an as-designed, as-built, and built appropriately. Together, they improve accuracy and collaboration and ultimately the success of construction outcomes. Being aware of their distinct contributions allows project stakeholders to manage their construction projects more effectively, mitigate risk, and avoid the costly desired and planned construction outcomes.

Shop Drawings: FAQs

Shop drawings are typically required in most projects. They are generally required in order to gain approval from an architect or engineer before any fabrication and/or installation, after it is determined that the shop drawings are in alignment with the design intent and regulatory constraints.

No. If a contractor has proposed a modification, it will need to be approved by the architect or engineer to maintain consistency with the original design.

Design drawings generally contain dimensions, but not to the level that is required for fabrication or installation. Shop drawings provide that level of detail.

Usually, the design team takes on the responsibility, but often the architect or engineer will lead the review of the shop drawings before starting construction.

CAD drafters, because of their accuracy, versatility, and efficiency, provide shop drawings that capture the latest design intent in a manageable manner that is easily executed.