Imagine that a project is being done, the deadline is strict, and the team finds out that one of the most important drawings has expired. Work stops, expenses go up, and everybody is frustrated.

Construction documents are not merely papers or PDFs but they are the oxygen of any project. They share plans, expectations, and compliance as well as safeguard everybody in an official capacity.

Here, we are taking a tour of each layer of construction documentation: what it entails, its creator, how it is managed and the importance of this layer of documentation in the success of a project. Also, we would discuss practical checklists, pitfalls to avoid, and the document life cycle that includes their creation and termination. Let’s start!

Key Roles and Purpose of Construction Documents

Construction documentation involves a lot of players. The professionals who see these documents are architects, engineers, contractors, subcontractors, and project managers; however, their duties vary:

- Architects create drawings and notes, driving design purpose.

- Structural, mechanical, electrical and plumbing contribution is made by engineers.

- Contractors interpret these documents to build on-site.

- Project managers organize, keep the revision under control, and control compliance.

The purpose is multifaceted. It is communication-based, coordination, compliance with the law, quality assurance, and risk minimization.

Imagine that in the following way: these papers are the blueprint of your project to be executed without problems. In their absence, minimal mistakes can lead to a delay, conflict, and expensive rework.

For help with digitizing your physical or PDF to CAD conversion, accurate, editable formats for better project execution, visit.

Key Components of Construction Documentation

Construction documentation isn’t just a bundle of drawings; it’s the entire communication system of the project, including every sheet, note, and specific working together so the field team knows exactly what to build, how to build it, and what done right actually looks like.

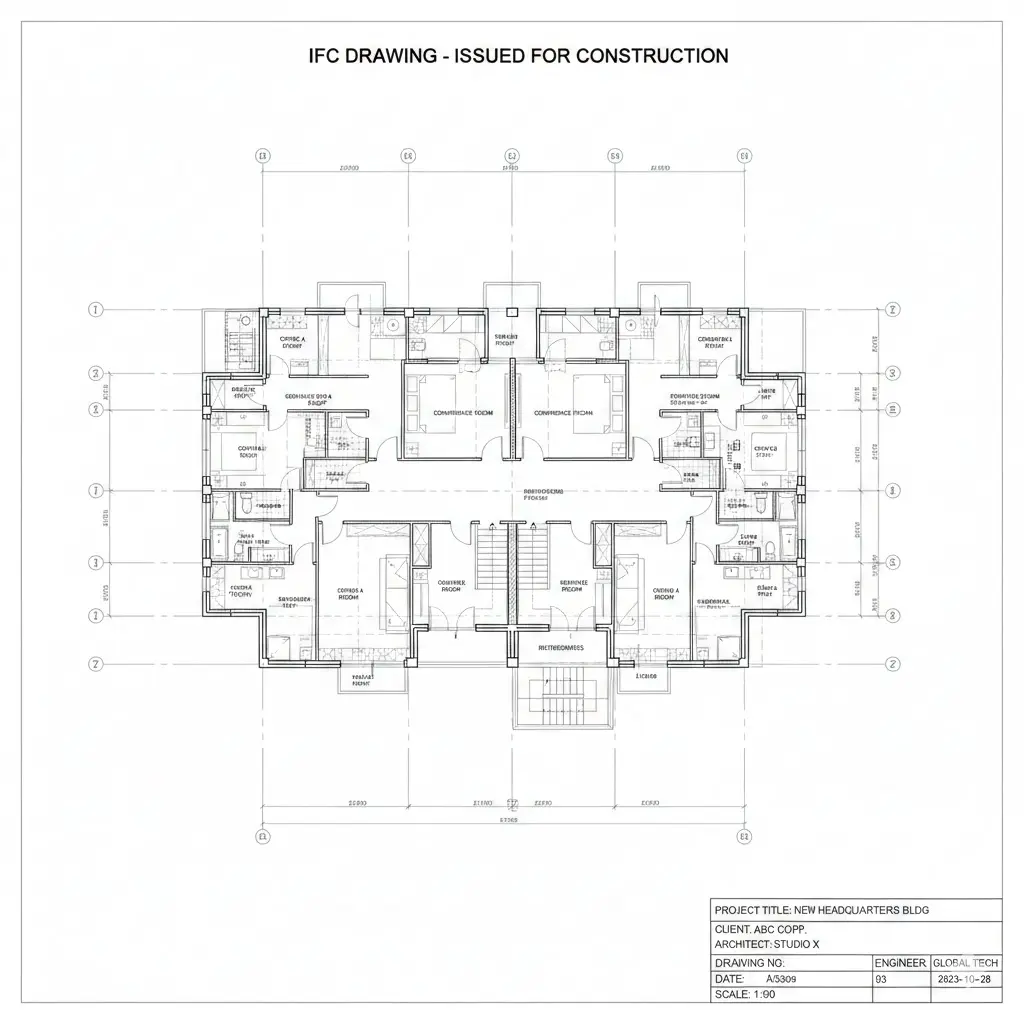

● Construction Drawings

The drawings are where most people start, and for good reason. They’re the visual roadmap of the project. Instead of throwing a long checklist at you, let’s look at how each discipline plays its part.

1. Architectural Drawings

You possess the architectural drawings, which determine the feel of the building, the floor plans, the elevations, and the sections that can lead everyone to visualize the completed space.

2. Structural Sheets

Right next to them are the structural sheets, the ones that quietly handle the heavy lifting. They map out the beams, columns, load paths, and foundation details that keep everything standing where it should.

3. Civil Drawings

Next, there are the civil drawings that look at the site, including grading, drainage, utilities, and the project’s connection to the surrounding world.

4. MEP Drawings

The MEP drawings weave all the systems through the structure. Mechanical handles airflow, electrical handles power, and plumbing brings water in (and out). These are the lifelines that make the building usable.

5. Landscape Drawings

And lastly, the landscape drawings bring it all together in the field, including the plants, paving, hardscape, and site features. They create the atmosphere of the way a space is experienced as one approaches it.

● Specifications

If drawings show the “what,” specifications explain the “how.” They cover material choices, quality expectations, installation methods, performance requirements, and the standards everyone needs to follow. When a drawing leaves something open to interpretation, the specs settle it.

● Schedules

Schedules never receive the attention they deserve, yet they are what everyone ends up looking at. They work out schedules, work cycles, equipment requests, finish choices, lists of fixtures and so on. A properly set schedule can assist teams in planning labor, deliveries, and inspections without stepping on each other.

● Architect Section

This is the part of the documentation that keeps the project moving without a dozen clarification calls. It includes symbols, legends, abbreviations, and general notes, basically, the translator who makes the rest of the drawings easier to understand. When the team is stuck, this is usually where the answer hides.

Boost project efficiency using our Guide to Construction Documents. Learn best practices, stay compliant, and keep teams aligned. Grab your free copy now!

Construction Documentation Types

Here are all of these:

1. Permit Set

These are the plans and papers that you file with the city to show that your project complies with the zoning rules, building codes, and local regulations.

A permit set normally contains items such as site plans, life-safety notes, elevations, and the simplest structural information, and anything the authority may need to certify that is adhered to.

2. Construction Set

This is the entire technical package with which the contractor has the actual construction of the project. It contains elaborate plans, sections, schedules, specifications and coordinated MEP/structural information.

Assuming the permit set informs the city of what you intend to construct, the construction set informs the field workforce precisely of how to construct what, in what size, of what material, how to connect it, what performance it is expected to meet, and how to install it.

3. Shop Drawings

Subcontractors, fabricators, or manufacturers create these to show how their specific component will be produced or installed.

Shop drawings drill deeper than design drawings, like custom steel connections, millwork layouts, windows and curtain wall assemblies, duct routing, or equipment anchoring. They confirm that what’s being fabricated matches both the design intent and real-world site conditions before installation begins.

4. As-Builts & Close-Out Documents

As-builts document what was actually constructed and not what was initially planned to be constructed. During the course of construction, modifications occur, such as field changes, RFIs, routing changes, replacement of materials, and the as-built represents all of this.

This package is accompanied by operation and maintenance manuals, warranties, equipment data and final inspections at the end of the project, providing the owner with a full history of the long-term maintenance and upgrades later.

5. Contractual & Legal Documents

These are the legal and financial foundations of the project. These are the contract, general, and special conditions, tender/bid documents, addenda, insurance, terms of payment, risk-sharing procedures, and dispute-resolution procedures.

Although they are not drawings, they are necessary as they spell out duties, safeguard both sides and create the manner in which the task will be handled in its entirety.

Guide on Construction Formats

● Standard Drawing Formats

Drawing sets follow a universal structure so teams can move through them without confusion. Sheets are grouped by discipline and ordered in a predictable sequence, making coordination quicker and reducing back-and-forth on-site.

● Sheet Naming Conventions

Every sheet starts with a discipline code.

- A for architectural

- S for structural

- M for mechanical

- E for electrical

- P for plumbing

This coding system lets teams find relevant information instantly during planning or installation.

● MasterFormat Overview

MasterFormat groups construction information into the following divisions:

- Concrete

- Metals

- Finishes

- MEP systems

It serves as a common language between designers, contractors, and suppliers so that specifications remain the same throughout.

● Versioning & Revision Control

The changed revision is followed using clouds, stamps, and logs to indicate what was changed and when. Keeping up with the most recent version eliminates the misuse of money, wastage, and conflicts during construction.

How to Read Construction Drawings

Reading construction drawings can feel like picking up a new language, but once you understand the basic cues, everything starts clicking into place.

● Symbol, Legend, & Notes

The symbols, legends, and notes are the first ones that should be familiarized with. These are the dictionaries of the whole set. They illustrate the way doors swing, what materials are used, where fixtures fit and how the elements combine. The other drawings will be guesswork unless you do this.

● Multiple Views

Then, use the various types of views, plans, elevations, sections and details.

- Plans display the project in a top-down manner, providing you with the layout and interrelationship of spaces.

- The heights expose the vertical surfaces, such as heights, finishes and positions of windows.

- The building is sliced through to reveal what happens behind the walls and floors.

- You can zoom in on details in a certain assembly to view how materials intersect and install components.

In the case of several disciplines, which include architectural, structural, mechanical, electrical and plumbing, coordination becomes a major factor. The drawings do not exist in isolation; the MEP lines have an impact on framing, structural loads on architectural walls and civil work on site utilities.

Common Difficulties in Managing Construction Documentation

● Coordination Issues

The alignment between architectural, structural and MEP drawings is not always perfect, and it is the point where clashes begin, like the ducts cutting through the beams, the position of walls changing, or the position of the fixtures in relation to the electrical plan being different.

The solution is easy but effective. Run regular coordination checks and use clash-detection tools early instead of waiting for the field team to catch the problem.

● Maintaining Version Control

One outdated sheet in circulation can break a schedule. You will witness groups of people unintentionally developing on a previous version due to the fact that a person sent a PDF some weeks back, and it has never been updated.

To avoid this, a centralized document management system should be used and ensure all revision is stamped, logged, and distributed from a single point of truth.

● Compliance and Regulatory Gaps

Missing code notes, standards that have been superseded, or missing permit information, tend to recall drawings over and over again to be revised. This delays the whole process.

The most suitable practice will be to check local codes initially at the initiation of the project and do a compliance check before anything is submitted for approval. A brief initial audit will normally save weeks of rework.

● Communication Gaps Between Teams

Designers assume that contractors know details; the contractors assume that designers have thought of everything, and misunderstandings enter in.

Establish a routine of organized handoffs: design reviews, pre-con meetings, weekly coordination calls during which any open questions would get recorded and addressed.

● Effective Management of Change Orders and RFIs.

Changes are essential, and when RFIs roll back and forth without replies or change orders that are not registered in the correct order, then the projects get derailed.

Establish a definite sequence of work, RFI submission to review, then response, revision update and finally distribution. Each of these steps must be time-stamped, and as such, nothing remains on the desk of a person and compelling them to make corrections in the field in a very short period of time.

Project Management & Tracking Documents

Construction documentation is not a mere case of drawings or technical specifications; this is also the administrative support that keeps a project on track. The documents provide managers with a real-time overview of the progress, cost and coordination.

● Milestones, Gantt Charts and Work Schedules.

Schedules and Gantt charts plan who does what and when. They indicate dependence between tasks, point out the critical paths, as well as assist the teams in planning how to allocate the labor, deliveries, and inspections. Major milestones are used to highlight the major milestones and ensure that everyone is on the same page as regards time constraints.

● Bill of Quantities (BOQ) and Cost Sheets

Costs of materials, labor and equipment are subdivided into BOQs and cost sheets. They assist in monitoring the real spending and budgeted expenses, early identification of overruns, and transparency within the team and stakeholders.

● Logs and Tracking of Procurements

Keeping tabs on ordered materials, approved final documents, and delivery timelines is essential. A clear log eliminates the chances of delays from missing items, avoids ordering duplicates, and ensures that critical components arrive just when needed.

● Site Reports, Daily Diaries, and Inspection Logs

Field teams record progress, occurrences and inspection outcomes in daily notes. Such records are exceedingly useful in accountability and dispute resolution, as well as in the provision of historical documents should problems emerge in the future. They also assist managers in identifying recurrent issues early enough before they become big.

Quality Assurance, Compliance & Risk Management

Construction documentation is not only about what people are to be building; that is the means of ensuring the project is safe, quality and of meeting all the rules. Correct registration reduces the chances of errors, eliminates disagreements and safeguards all.

● Inspection Reports, Safety Documentation, and Code Compliance

Frequent checks and safety records trace the compliance of work to the standard and the safety of workers during the work. The code compliance notes indicate that authorities and teams that design are in compliance with the legal requirements, so the amount of rework is not costly or fined.

● Change Orders, Variation Records, Addenda, and Punch Lists

Changes are common in any construction project. Recording all the modifications, be it a design change, a volume change used, or a change demanded by the client, makes it transparent. Punch lists are used to ensure that the items are completed systematically by the teams, and none of the items are left out before the handover process.

● Handover and Warranty Documents for Future Operations

The project does not end because the building is built. Operation manuals, handover packages and warranties provide the owners with proper documentation of the operation of systems and warranties. This paperwork is necessary to maintain it over the long term and prevent future surprises.

Construction Documents Checklist

- Sketches: Architectural, structural, MEP, civil, and site.

- Specifications: Materials, equipment, and standards.

- Schedules: Timelines and milestones.

- Contract/legal docs: Agreements, insurance, and additions.

- Revisions & approvals: Logs and stamps.

- QA/compliance: Certifications, inspection, and safety.

Final Deliverables & Document Lifecycle

Construction documents do not reside in a folder; they are like projects themselves; they undergo a lifecycle. At every step, deliverables are generated that are useful to a purpose that maintains the teams on track and the owners are notified.

● Permit Set & Construction Set

The process begins with the permit set, which is presented to the regulatory authority. Upon approval, it becomes the construction set, the finer details of drawings and specifications, which the contractor refers to to construct correctly.

● Shop Drawings and As-Builts / Close-Out Documents

Shop drawings are created to demonstrate how exactly components are going to be fabricated or installed by subcontractors and manufacturers. Once built, as-builts document the completed built conditions and capture the changes, field modifications, or design modifications.

● Operation & Maintenance (O&M) Manuals

When systems are installed, owners are given instructions, maintenance schedules and troubleshooting tips by operation and maintenance manuals. These manuals are also critical in maintaining smooth mechanical, electrical, and plumbing systems.

● Handover to Operations Team

All the completed drawings, manuals, warranties, and other appropriate paperwork are officially delivered to the team of operations or facilities. This makes the building easy to manage within the very first day.

● Archival for Maintenance, Renovations, or Legal Purposes

The final process is safe archiving. Documented notes are a source of information at a later stage of renovation, repair or even legally. A well-documented project is a guarantee of clarity and accountability even several years later.

Conclusion

Construction documents are not documents on paper; they are the key to a successful project. They minimize risk, maintain compliance, and hold each member of the team on track. If you need construction documentation professionals for excellent management, monitoring, recording, and updates, contact CAD Drafters!

FAQs

What do construction documents mean by?

They include construction project plans, drawings, specifications, schedules and legal/admin construction documents.

Who prepares construction documents? Why?

The construction documents are prepared by the architects, engineers, and contractors to control the execution, convey the purpose, and ensure compliance.

What are Gantt charts?

They are horizontal bar charts that construction experts use to set project schedules while considering visuals of each task. The charts give comprehensive data on starting dates, ending dates, project duration, affecting factors, and project progress.

What does a full set of construction documents have?

The set is comprised of drawings, specifications, schedules, contracts, permits, submittals, as-builts, and O&M manuals.

What about the revision of construction documents?

Take use logs, version control, stamps and approval workflows.

What are the major issues in construction documentation?

You may have problems with coordination, versioning, compliance, communication, and change management.

What benefits does correct construction documentation have in saving money and minimizing risk?

Proper documentation of construction saves money and lessens risk through avoiding mistakes, controversies, postponements and lawsuits.