Shop Drawing Services in Idaho

Construction schedules slip because drawings aren’t coordinated. This makes you anxious about missing deadlines, costly rework, and inspections that hold up payment. We solve that with precise, permit-ready shop drawing services in Idaho. Our technical layouts match field conditions, MEP coordination, and fabricator specifications. Including value, we ensure fast turnarounds, quick revisions, and files ready for fabrication, so your team builds and does not wait. Get a free quote now!

Healthcare Facilities

Commercial Complexes

Educational Institutions

Manufacturing Plants

Residential Developments

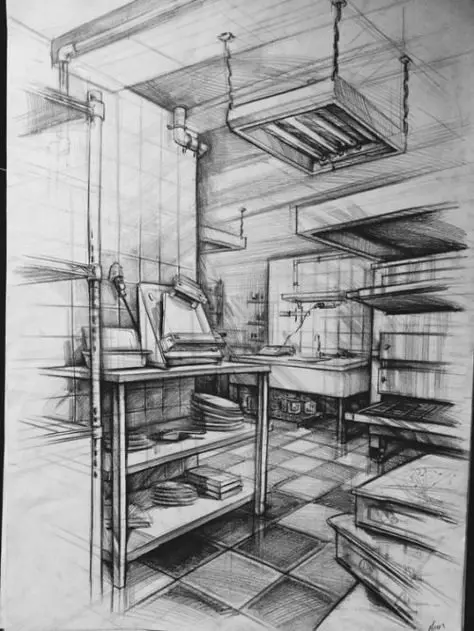

Hospitality & Retail Spaces

Boost Your Profits with Our Outsourced Shop Drawing Solutions!

Outsourcing lets you cut overhead while improving working capacity. You can experience fewer in-house hires, faster bids, and smooth coordination. Our freelance construction shop drawings team refines your workflow by delivering fabricator-ready details and clash-free models. Ultimately, you keep the project in control as we take the drafting load.

Reduced RFIs & Field Rework

We cut RFIs by coordinating MEP, structural, and fabricator details early. Our process includes clash detection and quality checks so field teams install right the first time. On average, clients report a 30–45% reduction in on-site rework on projects we support, which saves labor and schedule issues. We document with versioned PDFs and cloud logs to keep things on track.

Faster Permit & Fabrication Turnaround

Our drawings match code and project requirements, so permits and fabrication proceed without issues. We produce fabrication-ready DWGs and CNC files alongside annotated PDFs. Our team provides reports within 24-72 hours, ensuring you save maximum time on procurement, item selection, and long-lead durations. We also provide stamped submittals, vendor approvals, and proactive coordination.

Cost Savings & Predictability

Outsourcing reduces fixed staffing costs and converts labor to variable project expense. Our clients cut drafting overhead by 35% while improving bid accuracy. Using model-based takeoffs and vendor libraries, we lower material waste and change orders. Choose our shop drawing services in Idaho for standardized templates, vendor-specific details, and measurable ROI.

Need precise permit-ready plans fast? Contact our shop drawing company!

Shop Drawing Services for All CSI Trades

We’re a one-stop drafting partner for every CSI trade, structural, architectural, MEP, finishes, and specialty fabrication. We tailor deliverables to each project: permit-ready PDFs for authorities, detailed fabrication DWGs for vendors, BIM coordination models for clash-free installs, and cut-sheets for site labor.

Our quality control catches interface issues before steel or ducts arrive; clients face fewer RFIs and faster inspections. As a top choice among outsourced shop drawing services, we combine experienced drafters, standardized templates, and vendor libraries to speed approvals.

Unlike many shop drawings companies that hand off mismatched files, we map tolerances, coordinate anchors, and track revisions in cloud logs so your team and the trades stay aligned. Expect transparent scope, error-free options, and measurable reductions in on-site rework and schedule delays.

Steel Shop Drawing Services

We produce shop drawings for structural steel with connection details, bolt patterns, erection sequences, and fabrication-ready DWGs. CNC exports and tolerance checks minimize field rework. Our team coordinates anchors with structural engineers, provides stamped documents, and speeds fabrication to complete the project before the deadline.

Electrical Shop Drawing Services

Hiring us for electrical shop drawings means yoy will have details on conduit pathways, panel schedules, device layouts, and single-line diagrams. All the elements, including lighting, power, and low-voltage systems, are ensured to be coordinated perfectly.

Mechanical Shop Drawing Services

Mechanical shop drawings define HVAC routing, duct transitions, equipment supports, and service clearances in detailed elevations and sections. We deliver fabrication details, performance annotations, and clash-checked models.

Pipe Spool Shop Drawing Services

Our pipe spool drawings include isometrics, spool maps, weld symbols, cutting lists, and bending schedules for prefabrication. We produce nesting sheets and CNC-ready outputs for spool fabrication. Ultimately, our clear labeling, material specifications, and QC checks cut fabrication errors and onsite assembly delays.

Facade Shop Drawing Services

Facade shop drawings cover curtainwall sections, glazing patterns, mullion details, anchorage, and thermal breaks with wind-load verification. We provide fabrication files, assembly sequences, and mockup coordination while ensuring precise fabrication plans and sealant details reduce leak risks, speed inspections, and simplify exterior installation.

Millwork Shop Drawing Services

You can hire is for millwork shop drawing services. We transform design complexities into CNC-ready panels, joinery details, and finishes schedules. Hardware layouts are also included in our technical drawings for millwork projects.

MEP Shop Drawing Services

MEP shop drawings integrate mechanical, electrical, and plumbing into coordinated layouts with penetration schedules and access clearances. We deliver clash-free models, routed runs, and service annotations, ensuring your project stays on the right track.

Fabrication Shop Drawing Services

Fabrication shop drawings convert engineered parts into machine-ready documentation with nesting, cutting sequences, weld symbols, and assembly instructions. We include material handling notes, fabrication, and vendor-specific exports. Our QA checks and validated assemblies reduce rework and material waste.

Technologies We Use For Construction Shop Drawings

We use BIM coordination, CAD, automated drafting, cloud collaboration, AR/VR previews, and digital fabrication to deliver tightly coordinated shop drawings. That approach reduces clashes, speeds approvals, and powers fabrication-ready reports. Choose our shop drawing services in Idaho for faster installs, fewer RFIs, and reliable procurement timelines and measurable savings, too.

Building Information Modeling (BIM)

BIM creates federated models for clash detection, schedule integration, and accurate quantity extraction. We link 3D models to project schedules, producing model-based shop drawings that reduce coordination issues on-site.

Automated Drafting Software

Automated drafting uses scripts and families to speed repetitive detailing and meet standards. We use parametric templates to auto-populate annotations, reduce manual errors, and give CNC-ready outputs. That saves hours per drawing.

Computer-Aided Design (CAD)

Preferring standardized blocks and annotation styles, we create DWGs, meeting the project’s unique requirements. Our team ensures automated layer naming and export protocols to deliver machine-ready plans, reducing errors on-site.

Cloud-Based Collaboration

At CAD Drafters, we use cloud platforms to centralize regions and comments from team members. This eliminates conflicts and keeps everyone on the same page, saving time on approvals and rework.

Augmented & Virtual Reality (AR/VR)

AR/VR is used to identify access issues early. Our reviews produce visual sign-offs, reduce punchlist items, and align installers. Furthermore, our virtual mockups clarify routes, clearances, and connections.

Digital Fabrication & CNC Integration.

We provide CNC-ready files to feed fabrication machinery. Our digital fabrication reduces waste and optimizes material use. Through rigorous controls, we ensure on-time delivery, accurate assemblies, and reduced lead times.

Code-Compliant Shop Drawing Services In Idaho

Our well-crafted shop drawings, supported with local codes and structural integrity, help avoid rework. This further streamlines inspection, eliminates project delays, and ensures a first-time approval passes.

Furthermore, our shop drawings in construction include referenced sections, code citations, and stamped checklists so authorities and contractors can quickly approve. This minimizes hold-ups and keeps schedules and cash flows aligned with plans.

Here are the strategies we implement for code compliance

- Attach manufacturer datasheets, performance reports, and tested assemblies with clear installation notes.

- Dimension anchors, embed plates, and required clearances with load ratings matching the structural engineer's specifications.

- Provide stamped structural calculations and load paths for anchor design, bracing, and connection verification.

- List approved materials, finish fabrication, and report cross-references to prevent unauthorized substitutions on-site.

- Reference applicable code sections and local amendments.

- Specify fire-resistance ratings, penetration details, sealants, and inspection criteria.

- Annotate accessibility, egress widths, and maneuvering clearances to satisfy ADA, local, and safety requirements.

- Include erection sequencing, temporary bracing, and load conditions to keep installations safe during construction stages.

Our Transparent Construction Shop Drawing Process

Transparency matters for us. Therefore, we keep every stakeholder on the same page using cloud platforms, version control, and daily coordination. Our shop drawing services in Idaho provide digital markups, role-based access, and exportable revision histories so everyone can review the same files. This ensures auditable, collaborative workflows that speed approvals and foster precision.

Initial Project Review

We begin with a thorough feasibility analysis, collecting specifications, contract documents, vendor data, and site limitations. Our team runs a scope audit, identifies long-lead items, and logs critical dimensions. We create an initial BIM link and clash matrix, then deliver a clear project schedule for the shop drawing process.

Detailed Drafting & Coordination

Our detailed drafting combines trade-specific templates, vendor libraries, and parametric families. We run automated clash detection, coordinate anchors & penetrations, and annotate sequence and access. Drafters work alongside engineers to incorporate stamped details, and we issue revisioned PDFs, DWGs, and IFCs for smooth project coordination and help you avoid conflicts.

Final QA & Delivery

Our QA includes automated checks, audits, and professional reviews. We run dimensional verification, title-block validation, and coordinate vendor approval stamps. Deliverables include labeled PDFs, DWGs, IFCs, CNC files, and fabrication schedules. In the report, you will receive cloud-stored sets and project schedules, ensuring you have everything to move your project ahead with confidence.

Why Choose Us For Shop Drawing Services In Idaho?

Decades of combined drafting experience, certified BIM managers, and ISO-aligned QA processes make us the best choice in Idaho. We hold industry certifications in Revit, AutoCAD, and BIM coordination, and follow AISC and NFPA referencing where applicable. This blend of qualifications and practical shop drawing experience delivers accurate, auditable reports.

24/7 Customer Support

Our team is available around the clock for questions, rush submissions, and coordination calls. We maintain dedicated project channels, quick responses, and accelerated paths to keep your projects moving.

Tailored Services & High Affordability

We adapt deliverables and pricing to project size. Tailored scopes mean you pay only for needed outputs, keeping drafting affordable without sacrificing quality and estimation.

No Hidden Charges

At our shop drawing company, we provide upfront quotes, revision allowances, and transparent change-order quotations—no financial surprises, no hourly estimates; just predictable invoices.

Experts Producing Accurate Shop Drawings Through Proven Approaches

Our certified team applies reproducible, technical workflows to ensure precision in every drawing. Combining BIM technology, automated QA checks, parametric families, and CNC-ready exports, we create models that feed fabrication directly. This technical strategy reduces human error and produces measurable results.

Over 2+ decades, we have received thousands of appreciations from our clients: 30–45% fewer RFIs, 24–72 hour turnaround, and a 98% first-pass approval rate. Our team runs fabrication audits against vendor templates, verifies anchor capacities with labeled calculations, and simulates installation sequences in AR. This enables us to identify access issues early and mitigate them with effective plans.

Every set includes a verification log, clash reports, material takeoffs, and CNC nests when applicable. By standardizing templates and enforcing QA checks, we help you save on approval time, lower material waste, and reduce procurement lead times.

Our peer-review sign-off and ISO-aligned QA checklist improve profits, reduce onsite rework needs, and accelerate operations across commercial and industrial construction projects. Choose our shop drawing services in Idaho and benefit from repeatable, audit-ready processes!

Our Clients’ Reviews

FAQs

Do you offer revisions if changes are needed?

Yes. Every package includes a clearly stated revision allowance. We track changes in the cloud with time-stamped markups, and additional revisions are quoted transparently. For urgent changes, we offer speedy slots with predictable fees so schedules stay on track.

What formats do you use to submit construction shop drawings?

We prefer industry-standard formats, such as PDF, DWG, IFC/BIM federations, CNC/NEST files, and machine-ready exports.

Do you coordinate with architects, engineers, or subcontractors?

Yes, coordination is central to our process. We work directly with architects, engineers, and subcontractors to resolve issues before fabrication and inspections.

How do I request a quote for shop drawing services in Idaho?

Send project documents, including initial plans, specifications, RFIs, and related data, through our contact form or email. Include scope, desired deliverables, and project deadlines. We’ll review, provide a quote with turnaround and revision terms.