Shop Drawing Services in Kentucky

Building a Kentucky house costs around $250,000, and what ruins budgets faster than anything? Bad drawings. You need pinpoint accuracy from day one. At CAD Drafters, we provide shop drawing services in Kentucky, turning plans into buildable, permit-ready details so bids are tight and labor isn’t struggling on site.

Healthcare Facilities

Commercial Complexes

Educational Institutions

Manufacturing Plants

Residential Developments

Hospitality & Retail Spaces

Why Choose Us for Your Shop Drawing Needs?

Contractors prefer outsourced support because it’s faster, cheaper, and less headache than juggling in-house hires. As a trusted shop drawing company, we plug into your workflow and deliver consistent, construction-ready drafts that reduce RFIs and speed permitting.

Available All The Time

We keep rotating teams and cloud access so your project never stalls. Engineers and detailers are scheduled across time zones, enabling overlap during critical reviews. That means faster markups, concurrent trade coordination, and fewer hold-ups when schedules shift.

Unlimited Revisions

No one likes surprise fees mid-project. We offer unlimited revisions within scope, tracked, timestamped, and version-controlled. You get transparent revision histories and clear change orders so subcontractors always pull the current sheets.

24/7 Customer Support

Our support answers technical questions around the clock, smoothing overnight handoffs and weekend site issues. That’s why our shop drawing services in Kentucky maintain continuous communication, fewer misreads, fewer inspection delays, and better on-time milestones.

Get permit-ready construction shop drawing services in Kentucky!

All CSI Trades Covered with Professional Shop Drawings

Standing among the leading shop drawing companies, we consider ourselves a one-stop drafting partner for every CSI division, from structural steel to finish carpentry. We tailor templates, tolerances, and deliverables to each project’s specifications and local codes.

When you consider our outsourced shop drawing services, our teams follow strict QA, use BIM workflows, and maintain a 98% drawing-acceptance rate across repeat clients, proving reliability.

Here is the range of our shop drawing services.

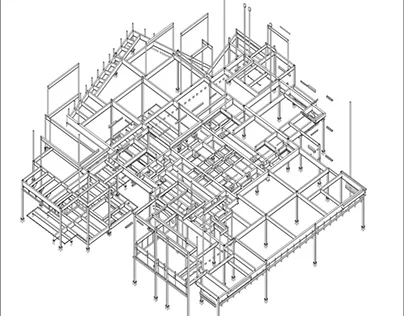

Steel Shop Drawing Services

Our steel shop drawing services are designed to show fabrication details, splice locations, plate dimensions, and erection sequencing for smooth installation. We prepare mill-certified parts, CNC-ready files, and bolt lists. Coordinated anchor plans and stamped submittals reduce field conflicts accurately and accelerate steel deliveries.

Electrical Shop Drawing Services

We produce electrical shop sets with conduit routing, load calculations, panel labeling, and fixture placement tied to circuiting. Vendor datasheets and breaker coordination reduce surprises. Layered DWGs with clear annotations clearly improve installer efficiency and reduce change orders during commissioning.

Mechanical Shop Drawing Services

Our mechanical shop drawings show equipment layouts, duct and piping routes, support details, and vibration isolation notes. We supply plans, sections, and fabrication details with performance tags. Coordination with structural and electrical trades prevents clashes, ensuring HVAC systems are installed the first time.

Pipe Spool Shop Drawing Services

We provide pipe spool drawing services that include isometrics, spool tags, material callouts, bend geometry, and weld preparation details for prefabrication. We deliver cut lists, nesting diagrams, and labeled parts for efficient fabrication. Accurate documentation streamlines transport, field alignment, and welding schedules on site.

Facade Shop Drawing Services

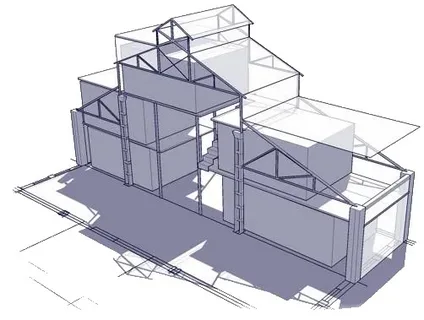

Our facade shop drawings present panel dimensions, connection details, drip edges, and thermal break specs for exterior systems. We prepare coordinate tables, wind-load checks, and glazing layouts. Detailed fabrication files and approved mockup references reduce punchlist items and speed façade installation.

Millwork Shop Drawing Services

We are famous for millwork shop drawing services. Our team specifies cabinet elevations, material schedules, joinery details, and hardware cutouts matched to installer workflows. We include CNC patterns, assembly sequencing, and finish tolerances. Precise templates and installer notes minimize site-fit adjustments and ensure design intent.

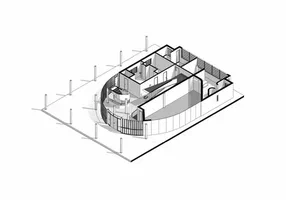

MEP Shop Drawing Services

Our MEP shop drawings coordinate HVAC, plumbing, and electrical layouts within structural constraints, showing penetrations, sleeves, and service access. We produce combined models and clash reports. Clear, consolidated shop sets cut sequencing conflicts, decrease RFIs, and keep multi-trade installation on schedule.

Fabrication Shop Drawing Services

We provide fabrication shop drawings to turn parts into production documents with part numbering, nesting layouts, weld symbols, and assembly blow-ups. We include material specs and handling notes for shops. Verified exports for plasma, laser, and CNC machines reduce scrap and rework reliably.

Strategies We Use For Highly Accurate Shop Drawing Services

Our shop drawing services in Kentucky involve a step-by-step process: model-driven drafting, trade coordination, iterative QA, and site-informed checks. That process reduces onsite issues and keeps schedules on point. We focus on local-specific codes and constructability.

Advanced Drafting Tools

We use model-based CAD and BIM platforms for dimensional accuracy and automatic quantity takeoffs. This enables ±1–2 mm detailing where required and faster revisions.

Strict QA Reviews

Our multi-stage QA includes automated clash detection, peer review, and a final lead-engineer signoff. This catches errors before permit submission and keeps approval rates high.

Team Coordination

Our dedicated project coordinators schedule daily coordination runs between trades, reducing RFIs by aligning MEP, structural, and architectural intents early.

Clear Layer Detailing

We prefer layered deliverables that follow your CAD standards: named layers, standardized lineweights, and annotation templates so contractors import sheets without rework.

Material Verification

We validate BOMs and material specs against vendor data and submittals, lowering procurement surprises and ensuring installable assemblies.

Error-Free Workflow

Our version control, cloud collaboration, and automatic change logs create an error-resistant process that’s easy to audit and hand off to field teams.

Fully Compliant Shop Drawing Services in Kentucky

Code-compliant drafting prevents stop-work orders and costly rework. Our deliverables match local and state requirements, so permits pass faster, inspections go smoother, and contractors stay on schedule and on budget. Our clear shop drawings in construction reduce inspection questions and keep projects moving flawlessly.

- IBC: International Building Code

- IRC: International Residential Code

- ASCE 7: Minimum Design Loads for Buildings and Other Structures

- AISC: Steel Construction Manual / American Institute of Steel Construction standards

- AWS: American Welding Society codes (D1.1 for structural welding)

- ASTM Standards

- UL: Underwriters Laboratories standards

- ACI 318: Building Code Requirements for Structural Concrete

Our Clear & Connected Shop Drawing Process.

We make the process visible from start to end. When you hire us for shop drawing services in Kentucky, we ensure every revision, comment, and model update is shared via cloud platforms so your team, subcontractors, PMs, and inspectors use the same up-to-date files.

Initial Project Review

First, we analyze plans, specifications, and site constraints, then produce an initial coordination report with priority issues flagged—typical turnaround: 24–72 hours for medium packages and a 10-point constructability checklist.

Detailed Drafting & Coordination

Next, trade models and 2D sheets are produced concurrently, clash-tested, and routed for review. We hold weekly coordination sessions and deliver annotated markups with delta views to speed approvals.

Final QA & Delivery

Last, final sets pass automated checks, lead review, and PDF/IFC exports. Files are stamped, packaged with BOMs, and uploaded to your cloud folder, ready for permit or fabrication with traceable sign-offs.

Benefits Of Working With Our Shop Drawing Team

We combine industry experience, certified CAD drafters, and construction-tested processes. Our certifications and continuous training keep standards high so you get consistent, buildable shop drawings that reduce on-site surprises and save time.

Ongoing Support

We remain available post-delivery for RFI responses, revisions, and field clarifications, so the team on site isn’t left waiting.

100% Customer Satisfaction

As one of the leading shop drawing companies in the state, we prioritize outcomes and measurable results. This is the reason many construction professionals partner with us for repeat projects and dependable reports.

Quick Delivery

Streamlined pipelines and template libraries let us fast-track shop drawings without sacrificing quality, ideal for tight bid windows and phased construction.

Benefits You Will Get After Working With Us

Hire a team from CAD Drafters and see tangible gains: an average 85% increase in workflow efficiency through coordinated BIM workflows; profit improvements between 8%–15% due to fewer change orders and improved estimating; a 98% bid win ratio for repeat clients thanks to faster, cleaner submittals; and roughly 20% business growth from smoother project turnover.

Our accuracy rates exceed 99% on critical dimensions, and our clash detection reduces onsite rework by over 70%. With our shop drawing services in Kentucky, you experience on-time project execution, clearer procurement, and fewer financial surprises; all of which directly save money and time.

Our Clients’ Reviews

FAQs

What software do you use to prepare and check your drawings?

We use industry-standard BIM and CAD: Autodesk Revit for models, AutoCAD for 2D details, Tekla for complex steel, Navisworks and Solibri for clash detection, and Bluebeam for review/markup. We also export IFC/PDF sets for fabricators and permitting.

Can your team handle multiple trades at the same time?

Yes. We run concurrent drafting streams with dedicated trade leads and a project coordinator who orchestrates daily clash runs and weekly coordination meetings to keep everything aligned.

How do your shop drawings help keep a construction project on track?

They reduce ambiguity: clash-free models, clear BOMs, and stamped submittals prevent onsite rework. That lowers RFIs, shortens procurement cycles, and helps inspectors sign off faster, keeping milestones intact.

How fast can you complete shop drawings for a medium-sized project?

Typical delivery for a medium-sized project (multiple trades, permit-ready) is 24-72 hours.