Shop Drawing Services in New Hampshire

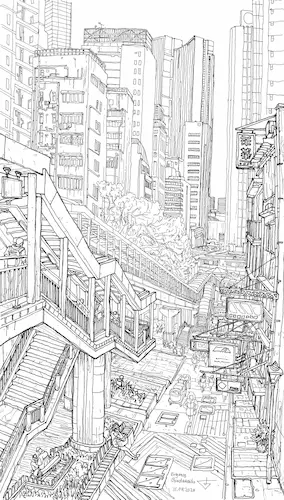

If you’ve built any structure in New Hampshire, you already know, construction drawings are essential for project success. One missed detail can trigger failed inspections, rework, and weeks of delays. That’s the pressure point. So, you need professional shop drawing services in New Hampshire to catch those issues early. If you are looking for the best partner for these services, we are here your help. Our precise drawings keep inspectors satisfied, labor aligned, and projects moving. Hire us to avoid time and budget overruns now!

Healthcare Facilities

Commercial Complexes

Educational Institutions

Manufacturing Plants

Residential Developments

Hospitality & Retail Spaces

How Our Construction Shop Drawings Boost Project Success

All GCs and subcontractors want clarity and precision to win the bid. We understand your challenges and help you with our digital workflows that ensure effective coordination, reduce rework, and improve the success ratio. Using structured checks and live updates, we help contractors cut field errors by up to 35%. Simply put, our shop drawings in construction speed approvals by removing friction from the way and keeping everyone on the same page, using proven methods.

Live Drawing Updates

You know how frequently plans change during construction. We adapt them and make changes, powered by real-time updates. Our system allows live drawing updates, so revisions don’t pile up or get late. We ensure that contractors always know which version is ready for use, removing outdated PDFs from the scene. This approach reduces rework needs and keeps all aligned.

Minimized Field Mistakes

Plans looking perfect on paper but not in the field is one of the biggest challenges GCs face. We resolve this issue under the cap of our outsourced shop drawing services. We eliminate field mistakes by 25-40%, coordinating dimensions and settling labor for a particular task. Benefiting from this early planning, you can save time and money on rework and reorders.

Optimized Project Scheduling

Time is money in the world of construction. If you want to save it like an expert, our shop drawing services in New Hampshire are the solution. We resolve coordination issues early to ensure you run the installation fast. There is no need to worry about mistakes due to hurry as we fill this gap with proper plans during the early stage of construction.

Ready To Work With Our Shop Drawing Company That Gets It Right the First Time !

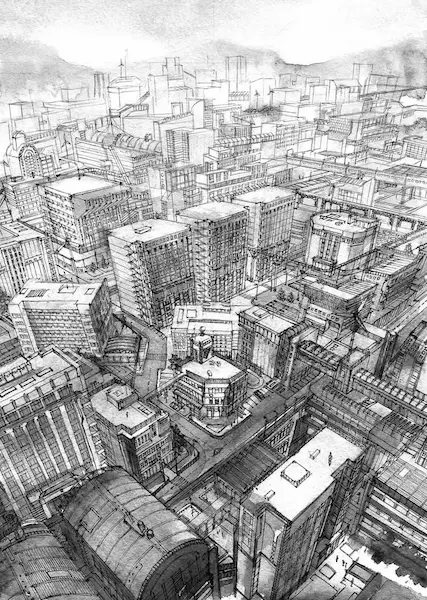

Comprehensive Shop Drawing Services For All CSI Trades

Misalignment and wrong drawings of different trades are the main reasons behind your losing the project. At CAD Drafters, one of the best shop drawing companies in your state, we have dedicated teams for each CSI trade. Bringing expertise of all at one point, we create technical layouts that revolve around the targeted project’s specific scope.

From material specifications to project timelines, everything is planned perfectly for each tarde. At the end of the assessment, a quality check is run to detect issues early and resolve them before they reach the construction point. Ultimately, you experience reduced RFIs, increased profit, and obviously a bid win with our assistance.

Steel Shop Drawing Services

These include detailed steel member layouts, connection details, and fabrication notes, aligning with structural intent and field conditions.

Electrical Shop Drawing Services

Hire us for electrical shop drawing services in New Hampshire, and we will provide a clear conduit routing, panel coordination, and equipment placement plan. This will support inspections and avoid site conflicts.

Mechanical Shop Drawing Services

We provide the best mecehnical shop drawings in your state and have achieved 96% client retention with excellent deliveries. If you hire us, you will get notes on coordinated HVAC layouts with proper clearances, access zones, and installation sequencing built in.

Pipe Spool Shop Drawing Services

Our pipe spool shop drawings include data on dimensions, weld types, and material specifications. Using this info, you can bid with detailed drawings, highlighting all risks with proven mitigation plans.

Facade Shop Drawing Services

When you hire us for facade shop drawing services in New Hampshire, we provide reports with panel layouts, anchorage details, and weatherproofing coordination. All the data is tailored to building envelope requirements.

Millwork Shop Drawing Services

Our millwork shop drawing report gives data on custom project details covering finishes, hardware, tolerances, and installation methods. You can save alot of money and time by using our reliable reports.

MEP Shop Drawing Services

Our MEP shop drawings are fully coordinated, including plans for all systems: mechanical, electrical, and plumbing. They help you reduce clashes and streamline multi-trade installations efficiently.

Fabrication Shop Drawing Services

At CAD Drafters, we provide facade shop-ready drawings to support prefabrication accuracy and faster onsite assembly without cost and time overruns.

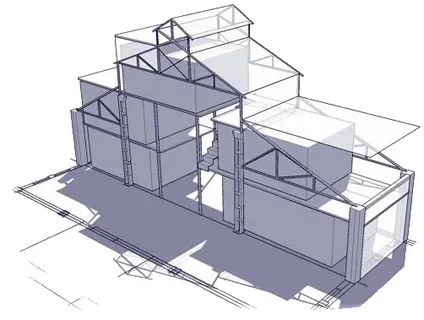

Technologies We Use In Shop Drawings

As accuracy is integral in our process, we ensure it using proven methods. Our team uses a mix of manual and digital methods to ensure you have the best outcomes after having our shop drawing services in New Hampshire. The integration of tools and software systems not only removes errors but also speeds up the process while keeping all things on the right track. From time management to risk detection and mitigation, everything is done digitally to have proper records if anything goes the opposite side in the future.

Virtual Reality (VR) Visualization

VR helps teams understand spatial relationships, access clearances, and installation challenges before materials arrive on-site. Using this, you can plan early and avoid issues later.

Augmented Reality (AR) Overlays

Using AR overlays, we connect drawings to real-world views. This helps contractors verify placement accuracy during installation phases, eliminating errors from the field work.

Parametric Modeling

Parametric tools let us update layouts quickly when dimensions or specifications change. Using this, we help you save on revision time while keeping mistakes almost zero.

Automated Quantity Takeoffs

Automated takeoffs (quantifying materials and labor) ensure material quantities align with drawings. This supports accurate procurement and cost control while ensuring you have high-quality, sustainable materials.

Building Information Modeling (BIM)

Our team utilizes BIM to visualize systems together. This tool helps us detect clashes early and improve coordination across all trades before construction begins, saving time and money.

Digital Measurement & Layout Tools

Using the digital measurement and layout tools, we improve measurement accuracy and reduce manual calculation errors during drafting and field coordination. This keeps conflict away from your plans.

Deliverables You’ll Receive

We are trusted by >90% of contractors in New Hampshire; credit goes to the team that submits comprehensive deliverables to the clients. Our group helps you streamline construction with all valuable data in hand, making you execute the plan with confidence.

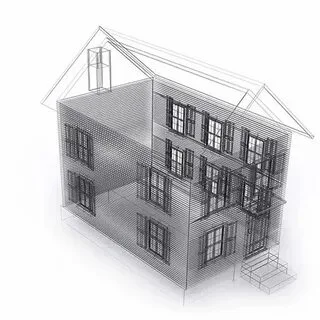

- Detailed shop drawings with accurate dimensions and installation notes

- Clash detection reports highlighting resolved conflicts

- Structured layer coordination for clear trade separation and easy navigation

- Material verification against approved submissions and specifications

- Verified dimensional accuracy aligned with site conditions and approved design documents

- Code compliance notes aligned with applicable local & national standards

- Assembly and installation instructions supporting fabrication and field execution

- Editable CAD files for coordination, revisions, and long-term project records

- High-quality PDF outputs ready for review, approval, and onsite use

- Complete revision version giving all updates and approval milestones

Our Proven Strategies for Accurate Shop Drawings

As already mentioned, accuracy is central to our shop drawing services in New Hampshire. Besides using tools and software systems, we integrate some human methods to get perfect results, including expert reviews, quality checks, dimensional validation, meetings with team members, recording and tracking, etc. All these strategies make our plans dependable for our clients.

Real-Time Revision Tracking

Our team tracks all the changes using cloud platforms, keeping data updated and ready for the next phase. This way, outdated data is flushed out on time, ensuring you avoid confusion and save time.

Trade Coordination Meetings

Dedicated teams working on different trades sit on a table, discuss points, identify conflicts, and resolve them on time, ensuring you have executable results in hand. These meetings are conducted frequently, so nothing wrong gets on the site.

Detailed Dimension Validation

Our shop drawing team ensures that all critical dimensions are cross-checked against construction site conditions and specifications. This helps you avoid layout conflicts and misalignment issues on the construction side, saving you from unforeseen expenses.

Our Streamlined Workflow Process

Speed, transparency, and accuracy; you can experience all these in our shop drawing services in New Hampshire. We have a well-organized process to create shop drawings for your taragted construction. You will not be in the phase where things juggle with each other; everything will be crystal clear in front of you.

Share Your Project

You send drawings, project specifications, desired schedules, and unique requirements. Our team will review everything to get the scope of work and plan drawings accordingly.

Drafting & Internal Review

After scope understanding, we draft structures, coordinate them, and run QA checks across trades and systems.

Final Delivery & Approval

At the end of the assessment, you’ll receive clear, ready-to-build drawings along with revision support. You can call us anytime for ongoing assistance.

Data We Need for Construction Shop Drawings

For good construction shop drawings, we always start with valuable information: solid, complete, and no guesswork. You need to provide approved design drawings, project specifications, schedules, and applicable codes to get shop drawings that actually work in the field.

Furthermore, for clarity, the experts at our shop drawing company need confirmed materials, selected equipment, and real site conditions. If something’s missing or still undecided, we will discuss it early instead of filling gaps with assumptions. Moreover, we review architectural, structural, and MEP documents together, because conflicts don’t live in one set. They hide between them. Hence, our early cross-checking saves time, RFIs, and frustration down the line.

At CAD Drafters, site limitations matter too, including access points, phasing plans, installation methods, etc. All this data helps us create drawings that level with your expected standards. This upfront collaboration is what keeps revisions from snowballing later. Contact our team for more details!

Feedback From Our Clients

FAQs

How do your shop drawings help reduce onsite construction mistakes?

We resolve clashes, confirm dimensions, and verify materials before installation, so problems don’t reach the field.

Can your team handle multi-trade projects simultaneously?

Yes. Our system is built for multi-trade coordination, including MEP, structural, and architectural systems.

What quality checks are performed before delivering shop drawings?

We run dimensional checks, trade coordination reviews, material verification, and code compliance audits before delivering shop drawings.