Shop Drawing Services in South Dakota

Projects look perfect on paper until the field proves otherwise. In South Dakota, construction output for the sector was about $2.37 billion in 2024, so details matter. Our shop drawing services in South Dakota turn plans into buildable, mistake-free sets. If you want drawings that save time and money, contact our team for a quick quote!

Healthcare Facilities

Commercial Complexes

Educational Institutions

Manufacturing Plants

Residential Developments

Hospitality & Retail Spaces

Professional Drafting Support for Architects, Engineers, & Builders

You’re struggling with deadlines, change orders, and permits, and we get it. Our shop drawing services in South Dakota back architects, engineers, and builders with fast, accurate shop drawings that cut rework. With 20 years on the tools, a 96% client retention rate, and a 98% bid-in success, we aim to make your life simpler. See how our services help each professional!

Architects

We translate your sketches into exact, code-compliant shop drawings so the contractor knows how to build what you imagined. Think of us as the translator between your design and the field. We check dimensions, tolerances, and material notes so fewer questions show up during construction. That saves time, stops delays, and helps you keep the design intent intact.

Engineers

Precision is your language. We produce steel shop drawing services, load-bearing notes, and connection details that match engineering calculations. Our drawings make prefabrication and field erection straightforward, covering welds, bolt patterns, and anchor layouts that are called out clearly. That reduces on-site surprises and keeps safety margins intact. If you design it, we’ll document it so fabricators and labor build exactly as intended.

Builders

You need clear shop drawings that run with your schedule. We deliver permit-ready sets, mechanical shop drawing services and clash-checked MEP drawings that reduce RFIs and cut rework. Our 24–72 hour delivery window and quick replies keep submission cycles tight. Fewer surprises mean fewer change orders, lower cost, and a faster path from foundation to finish. We track progress with weekly check-ins and on-demand revisions for every project phase.

Ready to Keep Your Schedule On-Point?

Stop delays before they start. Use our shop drawing services in South Dakota to lock down details early, cut RFIs, protect timelines, and keep your project moving. Talk to us today!

The Range of Our CSI-Divisions-Specific Services, Tailored for South Dakota

We cover the full CSI spectrum: structural steel, MEP, architectural finishes, and specialty fabrication. From permit sets to construction shop drawings that go straight to the fab shop, our team produces clear, coordinated documents. That means fewer on-site questions and faster approvals, so your project keeps moving.

We work with fabricators, general contractors, and specialty shops to create shop drawings in construction that respect welding, tolerances, and material lead times. Using BIM check and clash detection, we hand off models and 2D sheets ready for production.

Whether you need millwork layouts, facade details, pipe spool breakdowns, or electrical termination diagrams, we tailor deliverables to your shop’s workflow. Our QA checklist and peer review cut errors; our file formats match whatever system your fabricator prefers, so transition to fabrication is seamless every time, reliably too.

Steel Shop Drawing Services

Our steel detailing feeds the shop with precise databases, part lists, and fabrication instructions. We offer fabrication shop drawing services that include cut lists, nesting suggestions, and clear fit notes so steelwork ships ready to assemble, with minimal rework ensured.

Electrical Shop Drawing Services

Our electrical shop drawing services show panel schedules, conduit runs, and device locations with mounting heights and circuiting. We coordinate with lighting and fire alarm systems to prevent clashes. That clarity reduces electrician RFIs, speeds inspections, and ensures on-time electrical sign-off.

Mechanical Shop Drawing Services

Our mechanical detailing coordinates duct paths, equipment pads, and clearance needs for HVAC installs. We produce coordinated construction shop drawings that show trade interfaces, diffuser locations, and maintenance access, cutting field rework and ensuring systems operate as the engineer intended.

Pipe Spool Shop Drawing Services

Our pipe spool breakdowns list weld sequences, spool IDs, and bending radii so fabricators can cut, fit, and weld offsite. Pipe spool shop drawing services include ISO layouts and material callouts to speed QA checks and simplify field joins, speeding commissioning on every project.

Facade Shop Drawing Services

Our facade shop drawings model curtain walls, anchor patterns, and glass loads. Facade shop drawing services include gasket and mullion details, thermal breaks, and installation tolerances so installers set units that seal, align, and meet code without rework or delay claims.

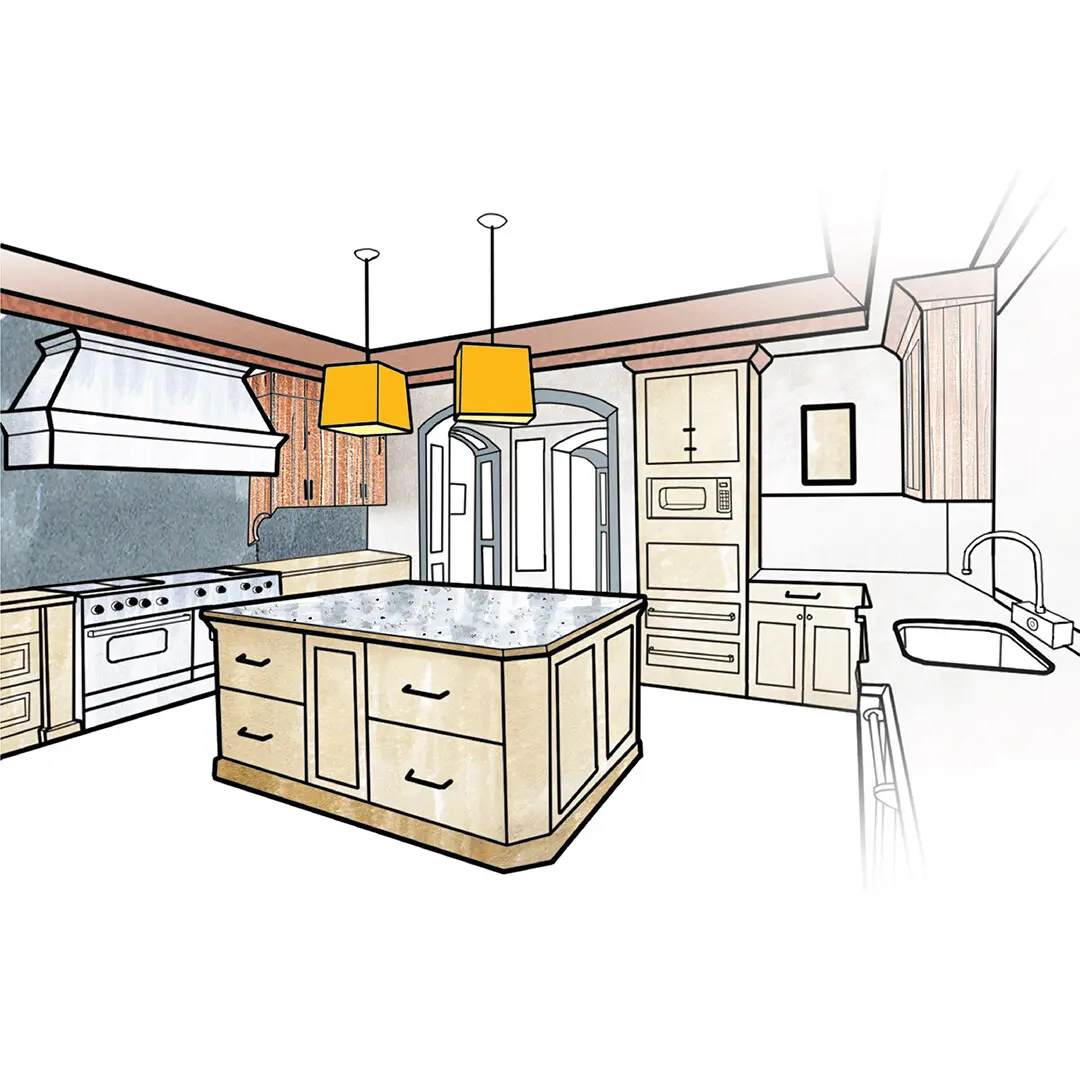

Millwork Shop Drawing Services

Our millwork sets show joinery, panel sizes, hardware sets, and finish sequences. We include cut lists, edge treatments, and installation templates so cabinetmakers and carpenters fit components cleanly, reducing field adjustments and preserving design quality through installation.

MEP Shop Drawing Services

Our MEP shop drawing services bundle duct, pipe, conduit, and equipment layouts into coordinated sheets and models. We verify clearances, maintenance access, and electrical loads so trades don’t clash. This hands-off coordination reduces RFIs and keeps inspections on schedule consistently.

Fabrication Shop Drawing Services

Fabrication drawings translate assemblies into shop sequences and CNC files. Our team annotates tolerances, finishes, and toolpaths so manufacturers run efficient cycles. As a committed shop drawing company, we deliver CAM files and 2D sheets that reduce setup time and scrap.

We Ensure Adherence to Local Building and Life Safety Codes

We design drawings that match South Dakota’s state and local codes, plus NFPA life-safety requirements. Our reviewers cross-check egress, fire ratings, and occupancy loads before release. That lowers permit comments and helps inspectors sign off faster, so construction stays safe and on schedule. We also coordinate plan stamps and issuance.

Egress & Means

Plan egress paths with door swings, corridor widths, and stair details to match occupancy loads. Our shop drawing services in South Dakota include our signs, exit lighting, and travel distances, so inspectors see compliance quickly. Clear egress documentation avoids stop-work orders and keeps laborers building.

Fire Ratings & Protection

Fire-rating schedules, wall section callouts, and through-penetration details are included so contractors can choose the correct assemblies. We verify firestopping, rated door frames, and sprinkler coordination early. That documentation reduces costly field fixes and helps sprinkler contractors stage work in the correct sequences.

Accessibility & ADA

Accessibility notes spell out clear floor slopes, ramp details, grab bar locations, and restroom clearances. We reference ADA guidelines and local amendments to ensure usable entrances and accessible routes. That reduces inspector comments and avoids retrofits that would hold up occupancy.

Structural Compliance

Structural notes flag load paths, connection tolerances, and embed locations so foundations and anchors line up. We coordinate structural details with shop drawings to prevent misaligned plates or mismatched embedments. That saves costly corrective work and preserves the schedule for concrete pours.

Electrical Safety

Electrical plans call out short-circuit data, equipment grounding, and panel feeder schedules. We coordinate with other leading shop drawings companies and electricians to confirm device counts and feeder routing. That coordination avoids missed circuits, reduces late addenda, and keeps commissioning on track.

Permit Coordination

We prepare permit sets with stamped cover sheets, code tables, and submittal checklists so officials see everything they need. Our package includes summary sheets, referenced standards, and a revision log. That completeness speeds the review clock and reduces reviewer back-and-forth.

How Do We Fill the Gap Between Design and Fabrication?

We close the gap between creative design and what the shop can actually build. Our systems map design geometry to fabrication constraints, highlighting impossible tolerances, and suggesting practical alternatives. We work with fabricators to optimize connections and reduce on-site adjustments. That partnership turns conceptual drawings into reliable shop packages, and it’s why our shop drawing services in South Dakota save time, materials, and headaches on every project. We prototype complex joints and validate connections with shop tests before release.

- BIM clash detection before any fabrication drawings are issued.

- Standardized part numbers tied directly to material requisitions.

- Tolerance tables per material and joint type included.

- Nested cutting patterns to minimize offcut waste loss.

- Prefabrication sequencing is organized around supplier lead time constraints.

- Weld maps and bolt torque specs for field crews.

- Template files for CNC cutting and punch operations.

- Clear packing lists to match shop bundles to trailers.

- 3D parts exported for virtual assembly checks pre-ship.

- Revision log embedded, so labor has the current drawings.

Minimize Material Waste with Our Optimized Cutting Lists!

When you hire us for shop drawing services in South Dakota, we optimize cutting lists to reduce scrap and control material cost. By nesting panels, aligning grain, and grouping compatible parts, our lists raise usable yield and lower purchase volumes. We validate lists against vendor sheets, factor kerf and saw tolerances, and share vendor-ready CSVs so fabricators cut efficiently and reduce waste on every order, saving time, money, and material costs.

Millwork Optimization

For millwork, we panelize cabinet faces, optimize sheet layouts, and sequence parts for glue-up and finishing. Cut lists include edge banding, veneer direction, and hardware pockets so shops don't overbuy material. We model assembly tolerances and provide nesting files to reduce veneer waste and speed production for interior finishes. That lowers shop lead times and prevents costly finish touch-ups during installation.

Pipe & Material Ordering

For piping, we calculate cut lengths, order extra fittings, and sequence spools by erection zone to reduce double-handling. Cut lists factor in weld preparations and coating allowances. By matching vendor pack sizes and scheduling deliveries to site needs, we minimize storage issues and reduce the chance of damaged or obsolete materials at handover. That saves budget and reduces environmental impact.

Nesting & CNC

Digital nesting reduces waste by arranging parts to use sheet edges and odd sizes. We export true-shape cut files for CNC routers and plasma tables, include kerf compensation, and plan sheet layouts to save material. Vendors get cut lists and machine files, reducing offcuts and lowering per-unit material costs across the project. This often cuts scrap by measurable percentages annually.

Get Detailed Connection and Assembly Instructions for Field Teams!

Our connection guides include bolt schedules, torque values, weld types, and sequencing so field teams build assemblies correctly. During shop drawing services in South Dakota, we annotate tolerances, shim locations, and inspection points with clear diagrams. That level of detail helps supervisors, reduces on-site questions, and speeds assembly, which cuts labor hours and keeps milestones on track. We provide printable pocket cards, sequence sheets, and digital checklists daily.

Field Assembly Guides

Our field guides give step-by-step assembly sequences with labeled parts and photos where helpful. Labor follows numbered steps, reducing missteps and rework. Guides align with revisions automatically for every shift.

Connection Details

Connection sheets show bolt grades, weld symbols, and torque sequences. We include inspection stamps and acceptance criteria so QA teams can sign off without guesswork, preventing rework in tight schedules.

Inspection Checklists

Our inspection checklists list hold points, required documentation, and test records. Inspectors and supervisors use mobile checklists to capture photos and signatures, creating a traceable record that speeds final approvals.

Get Local, Custom, Manufacturers-Ready Fabrication Drawings!

Local manufacturers need drawings that match their shop practices, and not generic templates. We meet shops where they are: exporting DXF/CAM files, tagging parts with shop IDs, and organizing bundles by trailer load. Our team visits shops when needed to verify attachments and tooling. This hands-on approach creates custom fabrication drawings that reduce setup time and speed first-pass production. We also provide kitting lists, sequencing, and arrival schedules to align with on-site labor.

Our shop drawing services in South Dakota include clear QA checkpoints: dimensional tolerances, inspection stamps, and measurement tables, so manufacturers inspect parts before shipping. We run peer review and a final cross-check against the model. When issues appear, we issue controlled revisions and notify affected vendors. That reduces rejected shipments and preserves project rhythm through steady deliveries. We call this routine quality control. Our measurement tables and acceptance criteria often shorten punchlist time at turnover by significant margins.

We adapt file formats to each shop’s CAM software, supply nested sheets, and export CNC-ready files. For specialty items, we include finish schedules, inspection templates, and handling notes to protect coated parts. Example: a local fabricator cut changeover time by 30% after adopting our package. That measurable improvement shows why local manufacturers choose our tailored approach. We support small runs, large batches, and emergency quick-turn orders with the same rigor across South Dakota consistently.

What Clients Say About Our Shop Drawing Services In South Dakota?

FAQs

What are shop drawings?

Shop drawings are detailed plans showing how parts fit together. They help builders, fabricators, and installers know exactly what to make and where.

How fast can you deliver?

We usually deliver shop drawings within 24–72 hours, depending on project size and complexity, but small items may be same-day.

Do you follow local codes?

Yes. We check South Dakota rules, NFPA and ADA notes, and adjust drawings so inspectors see code compliance during review.