Shop Drawing Services in Wisconsin

At CAD Drafters, we turn blueprints into a buildable reality. Our team knows local codes, millwork, and fabrication tolerances, so projects run cleaner. Whether you need shop drawing services in Wisconsin for a small remodel or a large fabrication pack, we deliver clarity, accurate details, and fast. Ready to stop rework and speed construction with clear build-ready files and guaranteed response times? Click the button now to get a free quote!

Hospitals

Commercial Buildings

Educational Institutions

Industrial Plants

Residential Complexes

Hospitality Projects

CAD Drafters: Your Trusted Partner for Construction Shop Drawings

Think of us as your on-call detailing team. We translate design intent into build-ready files that fabricators actually use. From coordinated elevations to bent-shop geometry, our outsourced shop drawing services in Wisconsin reduce RFI, change orders, and site rework. Our focus is practical: fast, accurate, and compliant with local rules, so your schedule holds, and bid numbers stay real, keeping your profits high.

Proven Experience Across Complex Builds

For more than 20 years, teams across the U.S. have relied on our construction shop drawings to move real projects forward. From small fabrication runs to multi-trade commercial builds, our experience shows up in fewer revisions, smoother approvals, and drawings that people actually want to build from. That consistency is why clients stay with us project after project.

Trusted by Contractors and Fabricators Alike

When general contractors, subcontractors, and fabricators all trust the same drawing set, projects move faster. We’ve earned that trust by delivering clear, coordinated files that reduce questions instead of creating them. Our 96% client retention rate isn’t an accident; it’s the result of drawings that hold up under real job-site pressure.

Accuracy That Holds Schedules and Budgets

According to leading shop drawing companies, mistakes in layouts don’t just waste time; they cost money. We focus on accuracy because it protects schedules, material orders, and labor planning. Clients tell us our drawings help them avoid late-night fixes, rushed field changes, and uncomfortable budget conversations. That’s how we help teams build with confidence instead of stress.

Get your shop drawing pack today!

Scope Of Our Shop Drawing Services in Wisconsin

From single-shop parts to full prefabricated assemblies, our scope covers every drawing type fabricators ask for. At CAD Drafters, we handle structural steel nodes, plate nesting, and erection sequences, detailed MEP isometrics, hanger layouts, and CNC-ready millwork elevations. Curtainwall and facade packages include wind-load callouts and connection details; piping spools come with isometrics, weld symbols, and material lists.

Furthermore, mechanical equipment setting plans and electrical panel schedules tie into riser diagrams so fabrication matches site reality. Each deliverable contains parts lists, tag schedules, and revision histories so shops move straight from PDF to production. We tailor drawings to Wisconsin DSPS plan-review expectations and common municipal requirements in Milwaukee, Madison, and Green Bay.

Our team prioritizes constructability, shortens procurement cycles, reduces on-site labor, and includes vendor approval notes and phased delivery schedules for smoother project closeouts.

Steel Shop Drawing Services

You can choose our shop drawing company to get shop-ready steel packages with member sizes, connection details, bolt patterns, plate nests, and erection notes. Our drawings include material lists, paint and galvanizing callouts, fabrication sequencing, and mill certificates references so your fabricator can quote and build without back-and-forth.

Electrical Shop Drawing Services

Our electrical shop drawings include single-line risers, panel schedules, load calculations, conduit and raceway runs, cable tray layouts, device elevations, and termination diagrams. We verify clearances, coordination with ceilings and MEP, and provide labeled schedules so electricians can install fast with minimal RFIs.

Mechanical Shop Drawing Services

We provide mechanical packages that cover HVAC unit setting plans, ductwork isometrics, diffuser and grille layouts, access panels, and equipment schedules. We coordinate piping interconnects with hanger locations, verify maintenance clearances, and deliver fabrication-ready files with tags, BOMs, and revision control every time.

Pipe Spool Shop Drawing Services

Our pipe spool drawings include full isometrics, spool breakdowns, bend schedules, weld callouts, flange orientation, and material lists. Each spool has clear tagging, nesting suggestions for cutting, and vendor-specific notes to optimize fabrication, transport, and rapid on-site tie-ins with QA criteria.

Facade Shop Drawing Services

We provide facade and curtainwall shop drawing services in Wisconsin that include unitized elevations, mullion details, thermal breaks, anchorage systems, sealant notes, and glazing schedules. Our team coordinates structure, air and vapor barriers, and attachment loads so installers can set units quickly and inspectors can sign off without ambiguity.

Millwork Shop Drawing Services

Our millwork shop drawings show elevations, section details, joinery, veneers, boardwalk layouts, CNC dimensions, material callouts, and assembly sequences. We supply cutlists and hardware schedules so cabinet shops produce units that fit field openings exactly, and installers finish quicker with minimal adjustment.

MEP Shop Drawing Services

Our MEP coordination packages integrate HVAC, electrical, and plumbing into a single coordinated model, resolving clashes and aligning systems with ceiling, slab penetrations, and equipment. We export discipline-specific sheets, markups, and clash reports that fabricators and subcontractors can trust during prefabrication.

Fabrication Shop Drawing Services

We provide fabrication drawings, covering shop-floor instructions, including nesting layouts, plate cutting coordinates, bend-back dimensions, weld symbols, tack points, and finishing notes. Our team includes CNC-ready DXF exports, tooling references, and QA checkpoints so fabricators can run efficient batches with fewer defects and tolerances.

How Do We Make Sure Our Shop Drawings Are 100% Perfect?

We ensure error-free fabricator and shop drawing services in Wisconsin by combining experienced detailers, triple-stage review, and fabricator feedback loops. That lowers shop rework, speeds procurement, reduces on-site adjustments, and shortens schedules. Wisconsin manufacturers get drawings tailored to local tolerances and DSPS expectations so production runs clean from first cut to final weld. We use model checks and automated clash detection with documented correction loops.

Detailed Project Review

We start by understanding every part of your project. Our experts study the design, scope, and specifications to ensure no details are missed before drafting begins.

Cross-Check With Designs

Each drawing is matched with the design and layout plans. This counterchecking also prevents any mismatch and makes sure that all the elements are perfectly fit to the project requirements.

Strict Quality Control

Our quality control team reviews each drawing before submission. It identifies and correct errors early to maintain high accuracy standards.

Automated Model Validation

At CAD Drafters, we automate model validation to verify dimensions, symbol consistency, and BOM reconciliation. Basic clash detection is also done during our process. This approach highlights missing data, cut mistakes, reduce conflicts, and keep construction on track from first to last phase.

CNC-Ready Outputs with Nesting Shecks

We deliver CNC-ready DXF and nesting files matched to fabricator tooling, with material takeoffs, part tagging, and tolerance notes. These outputs cut scrap, shorten machine setup, reconcile BOMs, and speed shop throughput, saving time and material cost on Wisconsin manufacturing projects.

Standardized Templates & Vendor Alignment

Standardized templates keep labels, tags, and numbering consistent so vendors can import data. We maintain vendor-specific templates and naming conventions, include anchor plans and bolt schedules, issuing export-ready files. This consistency reduces translation errors and speeds procurement and production coordination effectively.

Shop Drawings Based On Software & Technical Standards

We don’t use software just to draft faster, but we use it to make smarter decisions earlier. Our workflow connects models, drawings, and approvals into one clear chain, so nothing gets lost between design and fabrication. By aligning industry standards with local review expectations, our shop drawing services in Wisconsin help teams submit once, avoid rework, and move confidently from approval to production without delays.

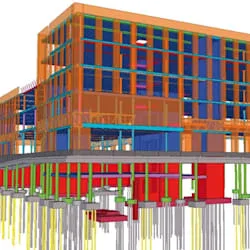

- Revit BIM coordination and model exports

- Navisworks clash detection and federated models

- IFC exports for interdisciplinary model handoffs

- CNC-ready DXF and nesting for fabricators

- AWS-aligned weld symbols and procedure notes

- AutoCAD drafting, DXF exports, CNC-ready files

- Bluebeam PDF markup, cloud reviews, submittals

- AutoCAD MEP layouts and isometric generation

- AISC-compliant steel connection symbols and tables

- DSPS code annotations for Wisconsin plan review

CAD Drafters: One of the Shop Drawing Companies that Maintain Rigorous Quality Control

Quality control isn’t optional; it’s how we ensure shop drawing services in Wisconsin that hit the floor without arguments. We combine automated checks, peer review, fabricator signoff, and documentation standards so you get fewer defects, predictable schedules, faster approvals, and peace of mind. Our layered QC saves time and protects your margins, and increases client satisfaction to nearly perfect levels consistently.

Automated Validation

Automated validation runs dimensional checks, symbol consistency, BOM reconciliation, and basic clash tests before human review, catching obvious errors early.

Peer Review

Our peer review pairs experienced detailers with different specialties to catch context errors, improve clarity, and ensure adherence to drawing standards.

Fabricator Signoff

We ensure the fabricator's signoff formally records shop feedback and acceptance on critical assemblies so production proceeds with documented approvals and fewer surprises.

Our Shop Drawing Workflow: From Concept to Submission

We believe shop drawings in construction shouldn’t feel like a black box. From day one, our process stays transparent: clear scope, visible progress, documented decisions, and no surprise costs. Clients always know what’s happening, what’s next, and why. That openness builds trust, keeps teams aligned, and makes approvals smoother without last-minute changes or uncomfortable budget conversations.

Initial Assessment

We clarify deliverables, select per-sheet, hourly, or retainer pricing, set milestones, identify contacts, and agree on acceptance criteria so teams know scope, costs, and decision points before any drawing work begins.

Modeling and Coordination

Next, we build a federated BIM model, run clash detection, assign responsible trades, resolve conflicts in coordination loops, and produce annotated markups, ensuring the shop model aligns with architecture and structure.

Outcomes

Last, we issue stamped submittals that include parts lists, revision history, installation notes, CNC-ready exports, and vendor templates; each package includes sign-offs so procurement, fabricators, and inspectors have clear documentary approval.

CAD Drafters: Wisconsin’s Local Shop Drawing Company

Wisconsin supported about 142,000 construction jobs in late 2024, so projects touch real businesses and families. That scale makes local accuracy non-negotiable; if drawings slow a fabricator, schedules slip, costs rise, and communities feel it. We design every shop drawing to match local tolerances, municipal review expectations, and fabricator workflows.

Wisconsin’s DSPS updates and adoption of IBC-based rules mean reviewers want code references and crisp submittals. We build checks for SPS 361–366 and the state’s code adaptations, so plan reviews run smoother and rework drops. Our deliverables include code notes and direct references to local acceptance criteria.

We don’t ship generic files when you hire us for shop drawing services in Wisconsin. Our detailers know regional tolerances used by Milwaukee fabricators and Madison inspectors. That local knowledge shortens RFIs, speeds procurement, and keeps trade contractors working. We sync drawings with vendor specs so attachments arrive ready to assemble, reducing shop adjustments and site delays.

Need a local team that understands Wisconsin codes and shop floor reality? Request tailored shop drawing services in Wisconsin! We’ll scope your job, provide transparent pricing, and deliver build-ready files that vendors accept. Start your free review and quick quote today!

Our Clients’ Reviews

FAQs

Can you provide engineer (PE) stamps or coordinate with my structural engineer?

Yes. We coordinate with your licensed engineer and can prepare submittals for their review and stamping. If you need us to arrange engineer stamping, we’ll connect you with a local PE partner and include timing and fees up front.

How many revision rounds are included with a submittal?

Standard packages include two revision rounds; retainer and project quotes can include more. Extra rounds are billed transparently. We track each revision, show changes, and keep the process tight so rework stays small.

How do you keep our drawings and IP confidential?

We sign NDAs on request, use secure file transfer (SFTP/secure cloud), and limit access to project teams only. If you have a vendor portal or specific security rules, we’ll follow them.

Can you match a fabricator’s shop standard or template?

Yes. Send a vendor template or sample submittal, and we’ll adapt our output to their layout, nomenclature, and tagging so the fabricator can run production without extra formatting work.

What BIM level of development (LOD) do you deliver?

We deliver from LOD 200 (schematic) up to LOD 400 (shop fabrication), depending on the scope. Tell us what your fabricator needs, and we’ll confirm the right LOD at the start so expectations match delivery.