Structural Steel Shop Drawings Services

Structural steel projects fall apart quickly when drawings leave too much open to interpretation. We focus on turning raw design intent into sheets that fabricators can follow without stopping to decode anything. Some drawings come together in a clean line or two; others need dense notes and connection details that only make sense after digging through the model. We handle both without turning everything into stiff, corporate-sounding paperwork. You get drawings that feel practical, readable, and grounded in real shop needs. No filler. No forced polish. Just usable information delivered fast. Here’s what you get with us:

20 +

Years Of Experience

1–2

Day Turnaround

40%

Less Rework

Our Specialized Structural Steel Shop Drawing Types

Our structural drafting services don’t force every project into the same template. Some builds need tight bolt schedules, others need connection logic spelled out, and a few just need a simple, readable sheet. We cover the full spread without making everything look factory-produced.

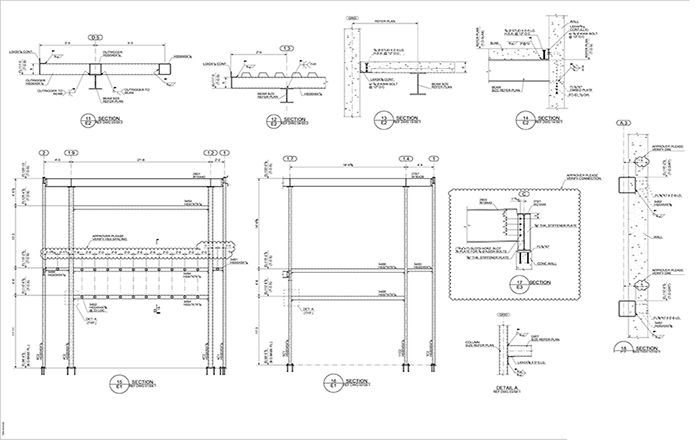

Structural Steel Shop Drawings

These structural shop drawings break the structure down into pieces that fabricators can actually build. Dimensions, holes, welds, and member tags show up where you expect them, not buried in a corner. We focus on clarity rather than page decoration.

Steel Fabrication Drawings

This set dives into member-by-member details; plates, stiffeners, bevels, and the odd modification that shows up only after reviewing the model. Each sheet gives fabricators enough information to cut, drill, and weld without hesitation.

Misc. Steel Shop Drawings

Handrails, ladders, guards, small brackets; these odd items often cause more delays than beams. We map them out with exact sizes, bends, and field-fit allowances so they don’t become last-minute surprises on-site.

Sheet Metal Shop Drawings

These sheets translate thin-gauge and formed metal components into buildable shapes. Flat patterns, folds, and edge treatments are shown plainly so the shop doesn’t waste time interpreting someone else’s guesswork.

Erection Drawings

Field crews need fast orientation, not a scavenger hunt. We produce erection plans that show piece marks, sequences, crane picks when required, and basic field adjustments without cluttering everything with fabricator-level detail.

Anchor Bolt Plans

Anchor bolts ruin schedules when they’re wrong by even an inch. We prepare layouts that include edge distances, embed plates, projections, and leveling plate details so foundation crews place everything correctly the first time.

Stair & Railing Drawings

Stairs are a blend of geometry and comfort, and railing requirements change from job to job. We map rises, runs, landings, and bracket spacing with enough detail that installers don’t need multiple calls to verify anything.

Connection Drawings

Some connections are straightforward; others hinge on loading, code limits, or geometry that looks odd until you model it. We document each connection with welds, bolts, plates, and edge distances clearly stated so the shop doesn’t guess.

As-Built Steel Drawings

Once everything is installed and final changes settle in, we update drawings to reflect the structure as it exists, not as it was originally drawn. These sheets help future crews avoid old mistakes and understand what actually stands on-site.

We Know And Follow Secrets Of Code-Compliance

Code-compliance looks straightforward from a distance; follow the rules, check the boxes, move on. But anyone who has worked with structural steel long enough knows the codes don’t always cooperate. AISC may say one thing, NISD adds another twist, and then OSHA steps in with safety layers that change how something must be detailed.

Residential work brings in IBC and IRC quirks, and suddenly a small adjustment in a flange or plate thickness becomes a compliance issue rather than a simple drawing fix. Our structural design drafting experts move through these rules without treating them like a never-ending maze. Sometimes a project needs LOD 300 clarity; sometimes it needs LOD 500 accuracy because the fabricator won’t accept “approximate” anything. The trick is knowing which level applies before the shop starts cutting steel, not after someone discovers a missing tolerance on-site. Our workflow blends Tekla, Revit, Navisworks, and other tools to catch conflicts early, but we still verify things manually because software doesn’t understand accountability. What you get is a set of drawings that match codes, field logic, and fabrication reality; not a binder full of rules nobody actually reads.

Perks Of Getting Our Structural Steel Shop Drawing Services

Faster Progress Without The Usual Back-And-Forth

We work with short turnaround windows, so drawings move through your workflow without long pauses. Because details are clear and consistent, fabricators don’t send constant clarification emails or calls, which cuts the usual slowdown dramatically.

Fewer Surprises During Fabrication And Erection

Clash checks, connection logic, and field constraints are handled early. That means fewer “fix it later” situations and a noticeable drop in rework. Even small elements (tabs, weld access, odd bolt spacing) get the same attention as major members.

Drawings That Match Shop Reality, Not Just Design Intent

Some structural steel drawings need LOD 300 accuracy, others demand LOD 500 precision. We adjust accordingly instead of forcing every job into the same level. Fabricators get sheets that reflect how the steel will actually be cut, welded, or installed.

Analyze Our Structural Shop Drawing Samples

2 Special Programs Used For Ideal Steel Shop Drawing Services

Some tools look powerful on paper but fall apart when the project gets messy. We rely on software that doesn’t panic when geometry gets twisted, tolerances shrink, or multiple trades collide. These programs let us track tiny issues before they become costly field corrections.

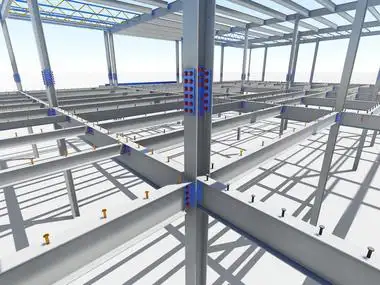

Tekla Structures

Tekla handles steel the way fabricators see it; piece by piece, plate by plate, connection by connection. It lets us model bolts, welds, seats, stiffeners, and awkward transitions without flattening them into approximate shapes. Because Tekla steel detailing flags interferences early, we don’t wait for the shop or field crew to discover them. It also supports LOD 100–500 work, so accuracy scales with project demands rather than forcing one rigid level.

Autodesk Revit + Navisworks

Revit gives us a controlled environment for coordination-heavy jobs where architectural and MEP elements squeeze steel into complicated spaces. Navisworks then becomes the referee, catching clashes and sequence issues that don’t appear on a 2D sheet. Together, they help us review assemblies, check tolerances, and confirm that connection logic won’t collapse when another trade shifts an inch. This combination reduces misalignments long before fabrication begins.

Trusted Clients

9 Steps We Follow In Steel Fabrication Drawings

- Initial Concept Review

- Modeling Primary Members

- Connection Drafting

- Anchor Layout Planning

- Secondary Member Detailing

- Clash Detection

- Sheet Generation

- Quality Verification

- As-Built Updates

Here’s What People Say About Our Steel Shop Drawings

Explore Our Full Range of Drafting and Production Sub-Services

Structural Steel Shop Drawings Company That Is Everywhere!

We operate out of San Diego, but our structural shop drawings rarely stay in one corner of the map. Steel projects don’t follow neat geographic lines, so we don’t either. Contractors in Texas ask for help on tight warehouse builds; teams in New York want complex connection detailing for mid-rise renovations.

When it comes to crews in Florida, they send us last-minute revisions because their field conditions change overnight. We handle all of it without treating out-of-state work like an inconvenience. Some weeks we’re deep into drawings for a fabrication shop in Colorado, the next week we’re supporting a mixed-use project in Illinois or a small industrial expansion in Arizona. West Coast GC firms tap us for seismic-sensitive detailing, and clients in states like Georgia, Washington, Nevada, and North Carolina call when their schedules shrink and they need drawings that won’t stall the crew. The point is simple: location doesn’t slow us down. As long as the steel needs to be modeled, checked, and prepared for fabrication, we jump in. Whether your project sits in a crowded urban block or somewhere with more cows than people, we deliver the same practical, clean, field-ready shop drawings every single time.

Take A Look At Our Various Previous Projects

Residential Housing

Commercial Builders

Hospitality and Hotels

Mixed-Use Development

Industrial Facilities

Institutional Projects

Frequently Asked Questions

What makes your steel shop drawings useful?

We create drawings that builders and fabricators can actually follow. They show exact dimensions, connection details, and notes needed on-site. There’s no guesswork or unnecessary fluff. The idea is to avoid mistakes before anyone picks up a welder or bolt.

How fast do you deliver drawings?

Small to medium projects often get drawings in 1–2 days from our structural steel shop drawings services. Bigger jobs take longer. We focus on what crews need first so work can start without waiting. Updates are shared as soon as changes happen.

Which codes do you follow?

We use AISC, NISD, and OSHA for commercial steel. For residential, we check IBC and IRC. Each drawing is reviewed so bolts, welds, and member sizes meet code, but we also think about how it goes together on-site.

What software do you use?

Unlike other structural steel shop drawing companies, we use Tekla Structures, Revit, Navisworks, AutoCAD, Fusion 360, and more. Each software solves a different problem, clashes, detailing, and fabrication checks. Deliverables can be DWG, PDF, RVT, or DXF, depending on what the shop needs.

Can you handle projects nationwide?

Yes. We work with teams in Texas, New York, Florida, Illinois, and beyond. Distance doesn’t matter. Drawings are fully coordinated and ready for fabrication even if we never visit the site.