The buildings resemble walls, windows and paint; however, what makes them liveable, safe and functional lies behind the scenes in mechanical, electrical and plumbing systems. Those are the MEP systems.

When we refer to MEP engineering, we are referring to the planning, designing, coordination, and installation of all those types of hidden systems that render a structure really usable. These involve the HVAC, water, power, drainage, ventilation, and safety systems, among others.

The absence of MEP makes a building a shell. But with nice MEP systems, it becomes a home, an office, a hospital, a functional space.

We are going to break it down in this guide: what the concept of MEP actually entails, how the process of design and implementation works, why it matters, the challenges of the concept and what modern technology and best practices can do to ensure that everything proceeds smoothly.

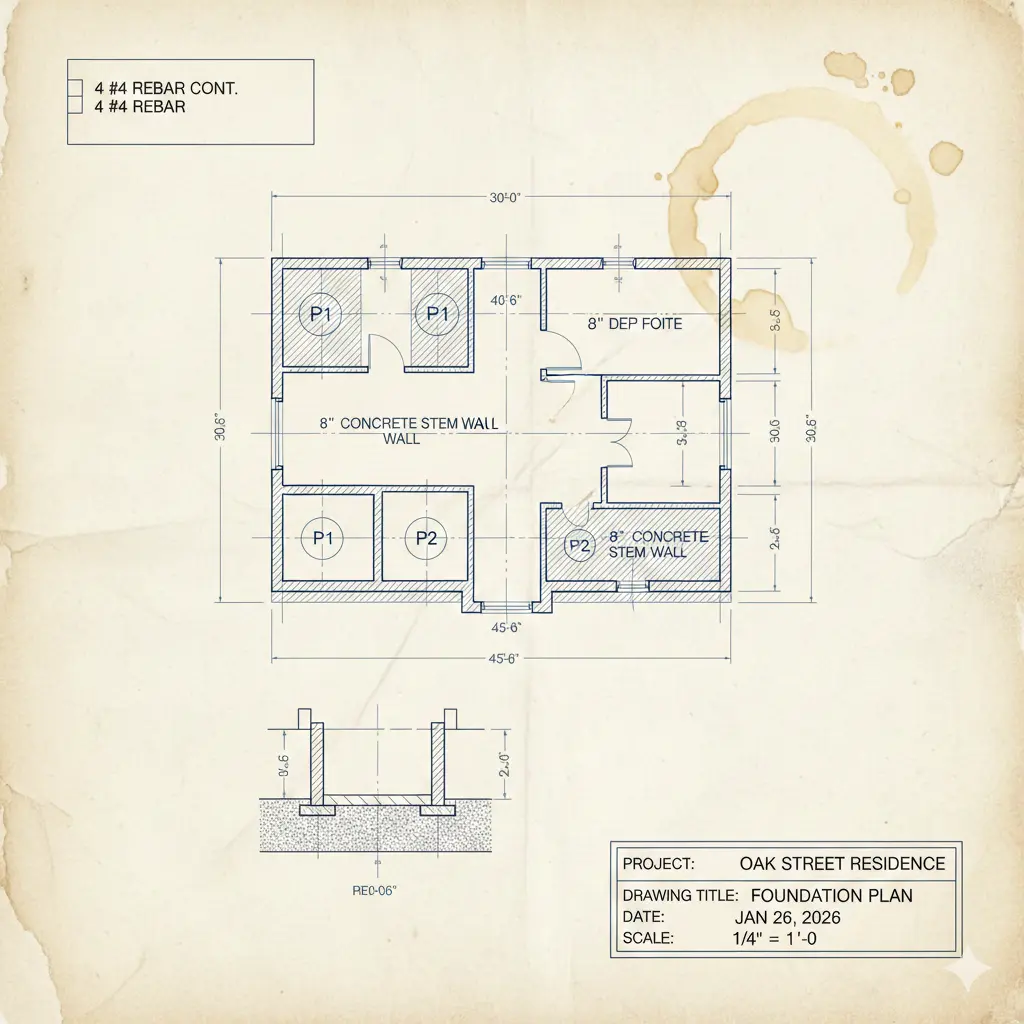

Explore how MEP details are translated into practical construction plans. The Difference Between Design Drawings and Shop Drawings

What is MEP Engineering?

MEP is an abbreviation that is used to refer to Mechanical, Electrical and Plumbing, the three fundamental skills that bring life to a building.

In simpler words:

- Mechanical covers heating, ventilation, air‑conditioning (HVAC), air flow, temperature control, air quality, sometimes fire‑protection, and smoke‑control systems.

- Electrical covers all power distribution, lighting, outlets, backup systems, safety systems (alarms, emergency lighting), communication systems, and wiring infrastructure.

- Plumbing handles clean water supply, drainage, sewage, waste management, hot‑water systems, sometimes gas piping, and sanitary requirements.

Why MEP Engineering Matters

MEP engineering does not simply involve sketching pipes or the installation of fittings. But it is a matter of aligning all these systems in such a way that they do not conflict with each other, spatially, functionally, or operationally. This also ensures that the systems are reliable, safe and efficient throughout the life of the building.

● Functionality

First, MEP enables basic usability. No plumbing means no water supply. No electrical planning means lights don’t come on. And similarly, no HVAC system means comfort, air quality, and even safety suffer. Buildings become unfit for occupation without MEP.

● Effective Plans

MEP impacts cost, schedule, and long‑term performance. Coordinated design reduces waste, avoids rework, prevents clashes, and ensures smooth installation and handover.

● Occupants Safety

Moreover, MEP forms safety, compliance, and sustainability. Code requirements are met with proper ventilation, fire-protection, safe electrical, and efficient water systems to protect occupants.

● Long-Term Building Performance

MEP prepares the grounds of efficient operations and maintenance throughout the years of building operation: proper documentation, as-built drawings, maintenance plans; that is what has made buildings operate in a tight manner year after year.

Mechanical, Electrical & Plumbing. What Each Does

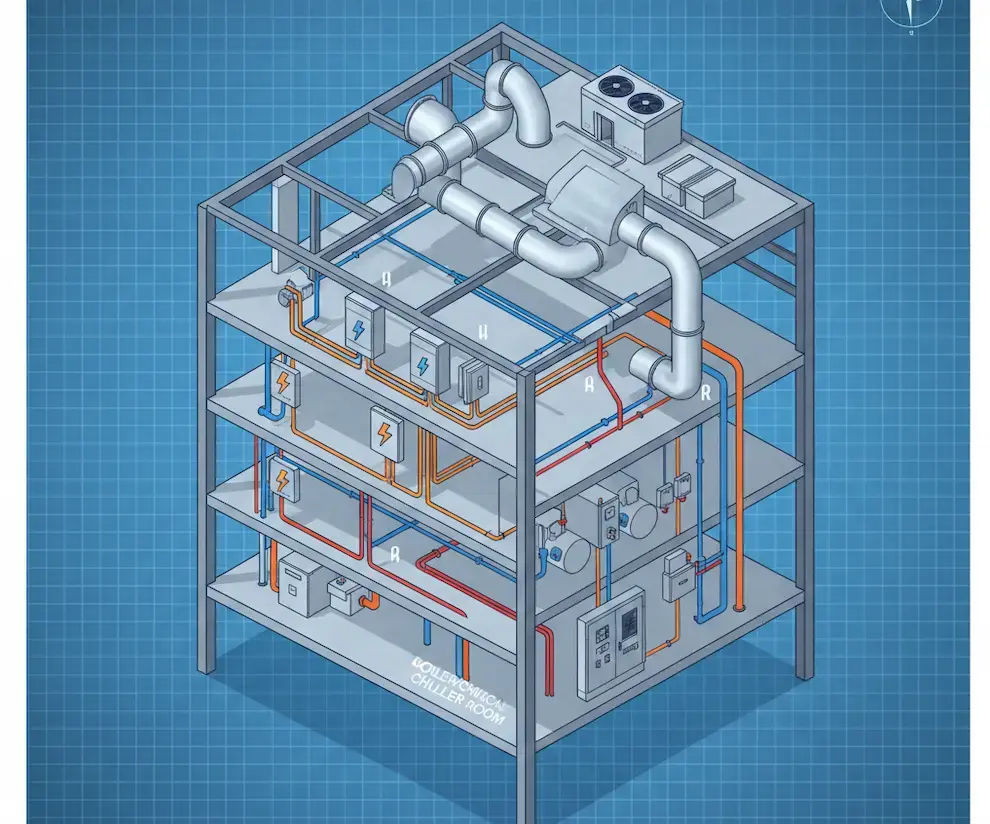

Buildings call for many invisible systems. MEP divides them into three core disciplines, each with distinct responsibilities, but all deeply interconnected.

1. Mechanical

This deals predominantly with HVAC (heating, cooling, ventilation and air quality control). It also includes ductwork, air-handling units, pumps, chillers, and hydronic as required.

The mechanical engineers compute heating/cooling loads, size equipment, lay duct routes, and provide airflow and thermal comfort to occupants. When done poorly, oversized chillers and badly laid ducts lead to performance tanks.

2. Electrical

Power is more than flipping a switch. Electrical design covers distribution boards, backups, lighting, emergency lighting, safety systems, control systems, communication wiring, and all power-hungry systems, like HVAC, lifts, and pumps.

Good designers also plan for future load, safe wiring, code compliance, and redundancy where needed.

3. Plumbing

Plumbing ensures a fresh water supply, drainage, wastewater, sanitation, hot water, and stormwater disposal.

It intersects with mechanical, e.g., hot‑water heating, HVAC condensate drainage, and electrical pumps & heaters. That’s why plumbing layout needs careful coordination with other systems to avoid conflicts or leaks.

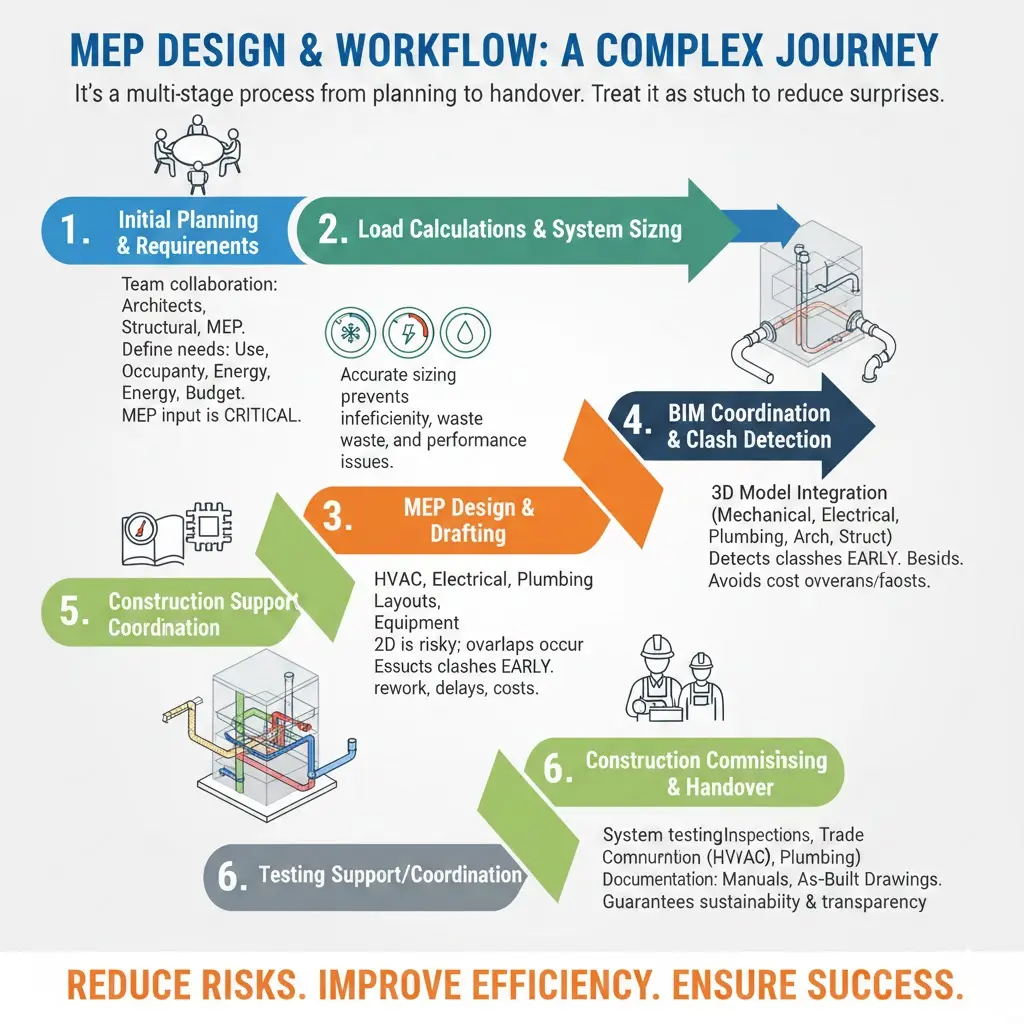

MEP Design & Workflow

MEP isn’t a side task; it’s a complex, multi‑stage workflow that runs from early planning to final handover. When you treat it as such, the risk of surprises drops dramatically.

Here’s how a MEP workflow flows and what to watch out for.

1. Initial Planning & Requirements Definition

The team is seated before any drawings. Architects, structural engineers, MEP engineers, planners; they have to get in line on needs, such as use of the building, occupancy, environmental comfort, code compliance, energy requirements, sustainability, and budget consideration. At this initial stage, it is necessary to include MEP. Without their input, layout decisions often conflict with mechanical or plumbing needs.

2. Load Calculations & System Sizing

Mechanical engineers calculate heating/cooling loads, airflow and ventilation requirements based on the requirements. Electrical engineers project power needs, lighting, emergency needs, and safety loads. And plumbing engineers measure the amount of water supplied, drainage, waste, and hot water.

This sizing will give you a sizing that does not over-size or under-size systems, causing performance problems, and it will avoid over-sizing, which will also waste energy and money. Excessive oversizing of HVAC, e.g., causes inefficiency and humidity issues.

Discover how modern technology is improving MEP design and execution. AI in Construction

3. MEP Design & Drafting

Now comes the drawings that include layouts, schematics, equipment placement, risers, ductwork, conduit runs, fixture plans, and distribution boards. Designing this in 2D is traditional, but risky becuase different disciplines may overlap without seeing each other.

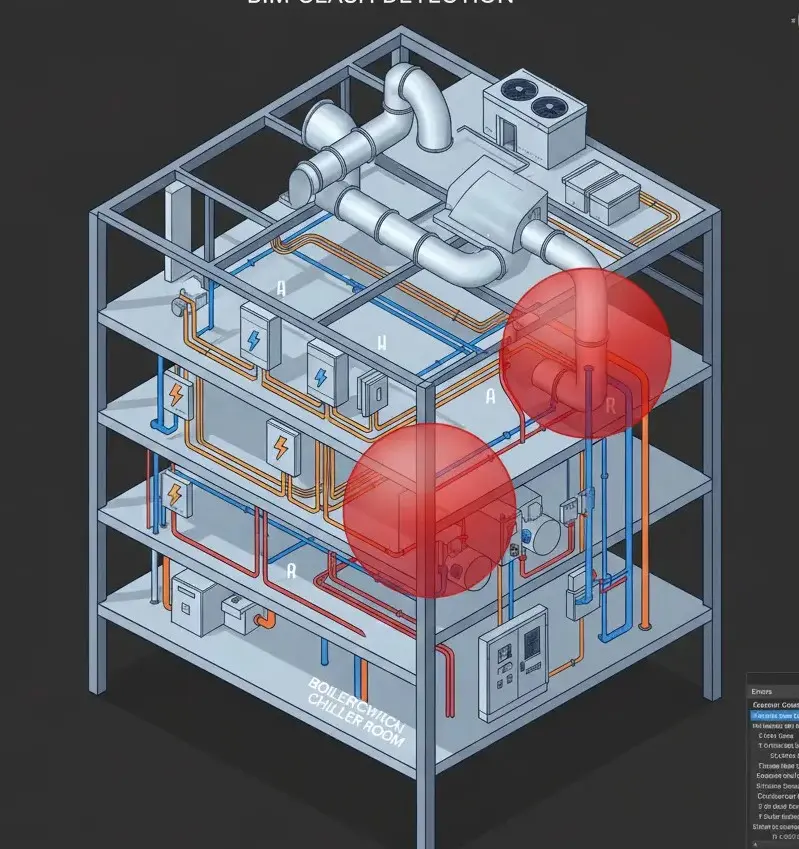

4. BIM Coordination & Clash Detection

This is where modern MEP stands out. With the help of BIM (Building Information Modelling), all the mechanical, electrical, plumbing, architectural and structural systems are combined into a single detailed 3D model. The ducts that strike the beams, pipes that traverse the electrical conductors and the lack of enough ceiling space appear at the initial stages before the actual physical construction begins.

Clash detection saves massive rework, delays, and unforeseen costs. It also provides access to maintenance, adequate clearances, and code compliance.

5. Construction Support/Coordination.

Once work begins, MEP engineers stay involved. They make replies to queries on sites, visit submissions, make sure that installations are done as per the designed plans, and get people trades to communicate with each other. Lack of this coordination may cause teams, unintentionally, to reverse a well-designed system and cause cost overrun or even system failure.

6. Testing, Commissioning & Handover

Once the system is installed, it should be tested; this includes HVAC air-flow, electrical circuits, plumbing pressure and drainage, control systems, and safety systems. Commissioning ensures that what is written on paper is real life. Operation/maintenance manuals, as-built drawings and test reports are some of the final documentation that is delivered to the owner or operator. It will guarantee sustainability, renovation planning, and transparency regarding future renovations.

Difficulties in MEP Engineering & Solutions.

MEP isn’t easy. There are many sources of risk. However, the majority of them are manageable, knowing what to look out for.

● Spatial and System Clashes.

Mechanical ducts, plumbing pipes, electrical conduits and structural beams are all competing to occupy space. Otherwise, it is a nightmare in case of installation or if systems are compromised.

● Codes, Compliance & Evolving Regulations.

The building codes, fire codes, energy efficiency regulations, and safety regulations are subject to frequent change. The early design and frequent review aid in preventing non-conformity, delays and redesigns.

● Coordination Between Teams

Lack of communication between architects, structural, MEP engineers, contractors and subcontractors at the initial stages leads to the production of inconsistent drawings, delays or even wastage. These problems should be prevented with early planning.

● Budget & Schedule Pressure

Time and cost constraints can push teams to rush design, skip coordination, or compromise on quality, which leads to problems down the line. The best defense is realistic planning and contingency allowances.

● Changing Project Scope Mid-Way

If building usage changes or requirements shift, systems may need redesign, rework, or upgrades. Good documentation, flexible design, and clear change‑management procedures help manage this smoothly.

● Maintenance and Future Proofing

The building’s lifetime spans decades. If MEP is designed just for now, future retrofits, maintenance, and energy code updates can be a nightmare. Therefore, design must account for future flexibility, documentation, and quality.

How MEP Differs by Building Type

MEP needs to change depending on what the building is used for. A hospital demands far more from MEP than a small residential block.

● Residential Buildings

Comfort, simple HVAC, plumbing, and power are all cost-sensitive, but comfort and safety remain important in residential projects. Plumbing and drainage design must be efficient, but mechanical and electrical loads must stay moderate.

● Offices or Commercial Buildings

These projects include higher electrical loads, HVAC needs, backup power, fire safety, more complex HVAC zoning, and stricter energy efficiency.

● Hospitals or Healthcare

Among the projects are increased electrical loads, heating and cooling requirements, back-up power, fire precautions, more intricate HVAC zoning and increased energy efficiency.

● Industrial or Industrial‑light Use

They require heavy mechanical systems, special plumbing, chemical handling, high power demand, stronger safety & code compliance, robust HVAC and ventilation connections.

● Mixed‑Use or High‑Rise Towers

These buildings require integrated MEP planning, vertical distribution systems, overlapping loads, coordinated fire safety, efficient plumbing stacks, and careful shaft and ceiling planning.

Ensure your building’s MEP systems are designed for efficiency and safety. Contact our experts today for a customized MEP solution.

How Technology & Modern Practices Transform MEP Engineering

The efficiency and accuracy of MEP engineering have never been higher than today due to the available tools and practices that were not available to the older generations.

● BIM (Building Information Modeling)

Combining architectural, structural, mechanical, electrical and plumbing information into a single 3D model is something that allows teams to detect clashes, route planning, visualisation of access to maintenance, as well as the creation of accurate shop drawings.

● Energy Simulation & System‑Performance Modeling

They assist in optimization of the HVAC, lighting and water systems to minimize the energy/water use, contribute to sustainability and the cost of operation.

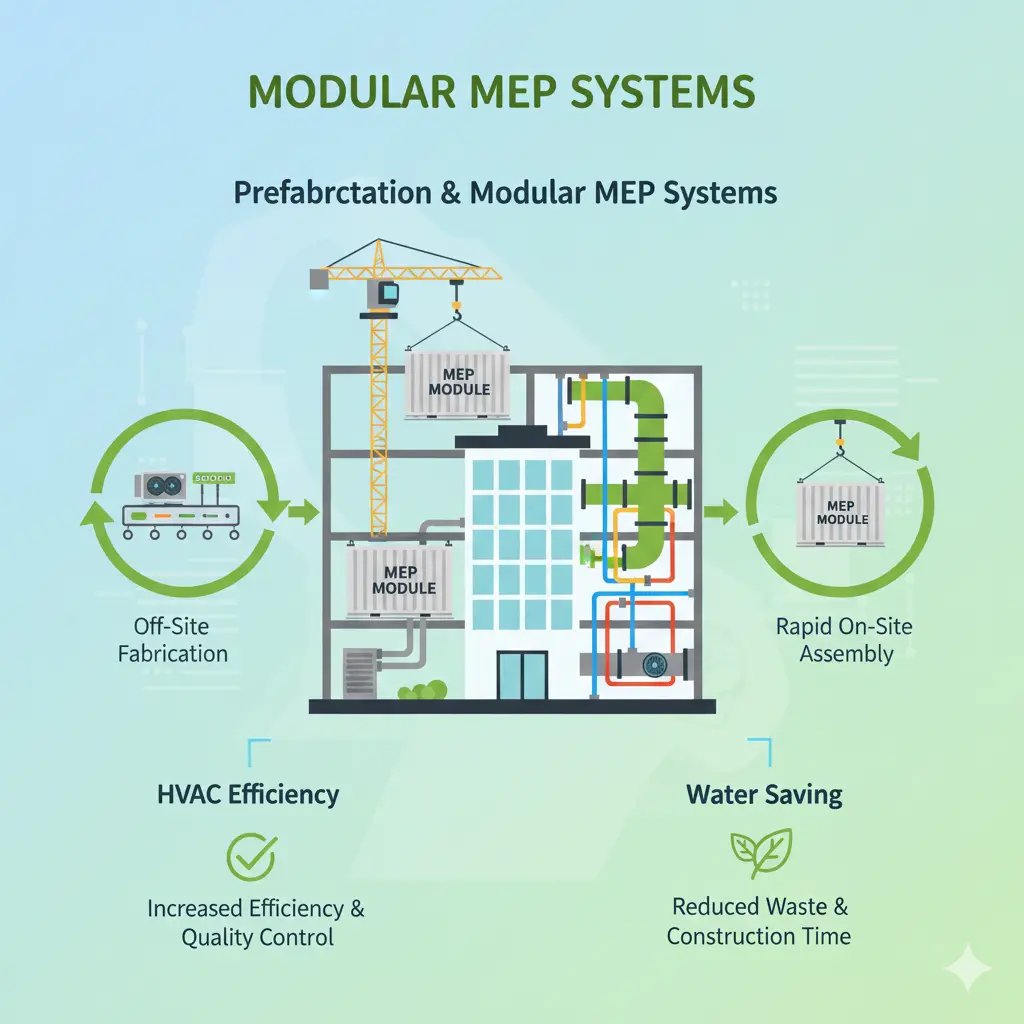

● Prefabrication & Modular MEP Systems

Such technologies offer ready-built units, modular bathrooms or MEP riser systems which require less on-site labor, enhance quality and accelerate the process of installation and reduce chances of rework.

● Building Integration, Sustainability.

They comprise efficient HVAC, water-efficient plumbing fittings, intelligent lighting, energy-efficient electrical design and align MEP long to run operational savings and green building objectives and targets.

Final Deliverables and Documentation

When a MEP process is well managed, you do not have scribbles or loose drawings left at the end of the process. You get:

- Complete MEP, mechanical layouts, electrical layouts, plumbing/drainage layouts, risers, sections, and details.

- Schedules and specifications of equipment such as HVAC units, pumps, panels, and fixtures.

- BIM models (when used) have clash-free coordination information.

- Commissioning reports and test documentation.

- As-built drawings and record documentation.

- Operation and maintenance manuals for handover.

- Clear documentation for code compliance, safety, and maintenance planning.

Conclusion

MEP engineering is the hidden backbone of every real building. It’s what makes walls live, what turns concrete into comfort, what powers lights, water, air, and safety. Do not pay attention to MEP; you create something weak, good on paper, terrible on the ground. Plan it, coordinate it, use technology, and have professionalism, and you create something that endures, delivers service and works.

When you have a project to work on, ensure that MEP is on the table at the onset. And in case of needing assistance in design, coordination or planning, a professional MEP engineering partner can save you time, money and a lot of headaches in the future.

FAQs

What is MEP design?

Planning, laying out, and sizing of mechanical, electrical and plumbing systems in such a way that they fit into a building design.

What is the way MEP engineering works?

It starts with needs and load calculations, transitions to detailed design and drafting, then BIM coordination, construction support, testing/commissioning, and eventually handover with complete documentation.

Why is MEP important?

A building cannot supply water, air, power and safety without MEP. Assurance of MEP is comfort, functionality, code compliance, energy efficiency and maintainability.

What is the role of BIM in MEP?

BIM permits simultaneous 3D modelling of all systems, creating system clash, coordinated design, proper documentation, and constructive construction to prevent expensive re-runs and system conflicts.

What are the issues related to neglecting or under-controlling MEP?

Common issues are system conflicts, building construction delays, cost overrun, poor HVAC or plumbing efficiency, code violations, uncomfortable occupants and high maintenance or rework.