Millwork & Casework Shop Drawings

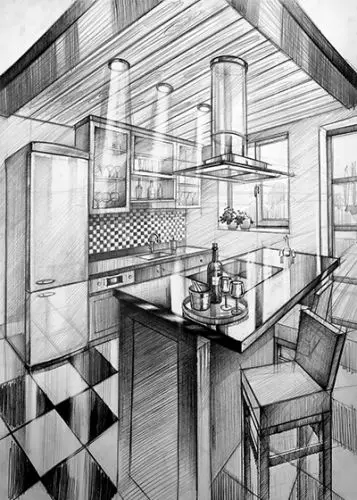

Success in commercial interiors is measured in sixteenth of an inch. We act as the technical engine for your commercial millwork shop. It helps the team deliver millwork shop drawings that transform architectural concepts into tangible construction data. Our drafting process prioritizes the interaction between varied materials (wood, stone, metal, and glass). This ensures every joint is tight and every reveal is intentional.

40% Reduction In Rework

AWI & NAAWS Grade Compliance

CNC Machine-Ready Data

9 Ways Our Drafting Services Support Your Shop

The range of interior finishes is broad, ranging from utilitarian storage to high-end ornamental features. Our millwork drafting services provide a universal language for your craftsmen, ensuring the design intent is preserved from the computer screen to the job site.

Institutional Casework Shop Drawings

High-traffic environments like schools and clinics require standardized and durable solutions. We provide casework shop drawings that focus on modular assembly, edge-banding details, and robust hardware integration for long-term performance.

Corporate Reception & Feature Walls

First impressions matter, and we understand that. Our experts detail the complex transitions between wood veneers, stone countertops, and LED lighting. It ensures the millwork drawings provide a foolproof assembly sequence for high-profile lobby areas.

Hospitality & Bar Millwork

From back-bar bottle displays to upholstered banquette seating, we provide the millwork drawings needed for the unique demands of the restaurant and hotel industry, focusing on both front-end style and back-end utility.

Healthcare Stations & Lab Benches

Hygiene and utility are the priorities here. We detail casework shop drawings that incorporate non-porous surfaces, anti-microbial joints, and integrated plumbing access for medical and laboratory settings.

Ornamental Trim & Profile Sections

We provide large-scale details for custom knives and profiles. Whether it's a historic restoration or a modern reveal, our millwork shop drawings company ensures every miter and cope is clearly defined.

Wall Cladding & Acoustic Wood Systems

We detail the sub-framing and attachment systems for wall panels and wood slats. Our drawings ensure perfect alignment with existing MEP (Mechanical, Electrical, Plumbing) penetrations, preventing site conflicts.

Retail Fixtures & Brand Environments

Retail moves at the speed of the consumer. We provide millwork shop drawings services for cash wraps, point-of-sale kiosks, and product displays, optimized for rapid shop fabrication and easy on-site assembly.

Bespoke Architectural Millwork Detailing

For those "one-off" feature pieces, we provide intricate millwork drawings. We tackle complex radii, curved paneling, and unique ceiling baffles, providing the structural section details necessary for secure and beautiful mounting.

Solid Surface & Stone Coordination

Millwork is rarely a solo act. Our millwork drafting services include precise detailing for stone tops and backsplashes, ensuring that the cabinetry and the stonework align perfectly without expensive field trimming.

Nationwide Millwork & Casework Shop Drawings Support

The Architectural Woodwork Institute (AWI) sets the standard for the American market. As a premier millwork shop drawings company, we ensure your submittals meet the exact grade (Premium, Custom, or Economy) mandated by your project’s specifications.

Whether you are a truss shop drawing service company in Boston, handling a university lab, or a contractor in Los Angeles installing a sleek corporate headquarters, our team adapts to your regional codes. We understand the specific moisture-control requirements for wood in the Pacific Northwest versus the humidity of Florida. By choosing to outsource millwork shop drawings to a firm that understands the US construction cycle, you ensure that your submittals move past the architect’s desk and onto the shop floor without costly revisions

How Professional Drafting Protects Your Profit

Eliminating On-Site Improvisation

A cabinet that is an inch too wide is a disaster. Our casework shop drawings utilize field-verified dimensions to ensure every filler and scribe is perfectly accounted for, making installation a fast, no-surprise process. This clarity reduces the time your crew spends on-site, directly increasing the profitability of the project.

Faster Approval Cycles

Architects and designers respect AWI-standard documentation. Our millwork drafting services provide the professional clarity (from finish callouts to detailed hardware schedules) that reduces the back-and-forth during the submittal phase. We help you get approved faster so your shop can start cutting.

Precision Material Procurement

Accurate millwork shop drawings allow for exact material take-offs. You won’t be over-ordering expensive exotic veneers or specialized laminates. We help you buy exactly what you need, which is essential for protecting your margins in a market of fluctuating material costs.

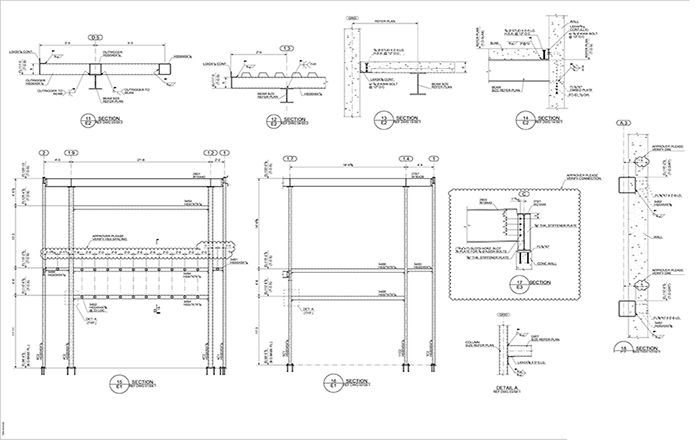

Check Our Casework Shop Drawings and Samples

Innovative Tools Powering Our Millwork Output

CAD Drafters is known for multiple services. We ensure every model is code-compliant and precise. That’s why most of our models turn out extremely beneficial for the contractors. Here are two of the best tools and tactics that improve our millwork models.

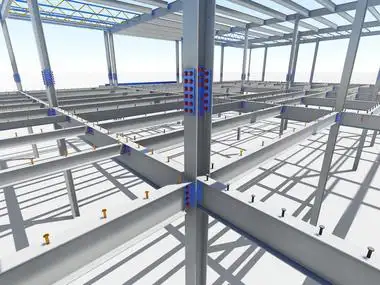

Multi-Dimensional Coordination & Virtual Assembly

In modern construction, the as-built reality rarely matches the as-drawn blueprints. A core pillar of our millwork shop drawings services is the creation of 3D digital prototypes. We model the casework within the 3D site context to identify hard clashes with HVAC ducts or structural beams. This proactive coordination ensures that when the millwork arrives on-site, it fits the environment perfectly. By resolving these conflicts in the virtual model, we eliminate the need for field-cutting pre-finished panels, which is a massive cost-saver for veneered or high-gloss projects

Digital CNC Extraction for Automated Shops

We provide a screen-to-machine advantage for the high-tech commercial millwork shop. Beyond the submittal set, we generate part-level data and nested layouts for your CNC machinery. This includes exact boring patterns for hinges, cam-locks, and shelf pins. This service allows your fabrication team to skip the manual layout phase entirely. By feeding our data directly into your production software, you reduce human error, minimize material waste, and significantly increase the throughput of your shop, allowing you to hit aggressive delivery dates.

Trusted Clients

9 Reasons We Excel Beyond Other Millwork Drafting Firms

- Comprehensive Hardware Schedules

- Scalable Resources

- Proven US Reliability

- Multi-Material Coordination

- Direct Communication

- Advanced Software Suite

- AWI Standard Expertise

- Fabrication-Savvy

- Rapid Turnaround

Verified Success Stories

Here Are Some Of Our Related Shop Drawings Services

Scale Your Operations with Strategic Outsourcing

The drafting room is often the bottleneck of a successful woodshop. When you outsource millwork shop drawings, you gain the ability to scale your operations instantly without the overhead of additional salaries and software licenses. Many millwork shop drawing companies rely on freelance models, but a single individual often lacks the bandwidth for large commercial submittals. Our company provides a managed, team-based environment that can handle massive casework packages while maintaining a single point of contact for your project manager.

Choosing to outsource millwork shop drawings to an established millwork shop drawing company gives you access to the latest software and AWI-aware detailers. Our online millwork drafting services act as an extension of your shop floor. We adopt your unique construction methods and hardware preferences, ensuring that the final millwork and cabinet shop drawings match your shop’s specific fabrication DNA, allowing your master craftsmen to focus on building rather than drafting.

Our Massive Shop Drawing Portfolio

Residential Projects

Commercial Buildings

Government Projects

Apartments and Hotels

Industrial Structures

Historic Projects

Frequently Asked Questions

What file formats do you provide?

We deliver full PDF submittal sets, 2D DWG files, and optional CNC-ready part files or 3D IFC models for BIM coordination.

Can you match our shop-specific joinery?

Yes. Whether you use dowels, blind-dados, or cam-locks, our millwork drafting services are customized to reflect your specific fabrication methods.

Do you handle the hardware submittals?

We include a comprehensive hardware schedule in our millwork drawings, identifying manufacturer part numbers and finishes to match your project specifications.

How do you handle site measurements?

We can work from your hand-sketched field notes or point cloud data. We always flag “Verify in Field” (VIF) areas to ensure the ultimate fit is perfect.

Why choose a company over a freelance millwork shop drawings provider?

A millwork shop drawings company provides the insurance, the multi-stage QA/QC, and the manpower to meet the deadlines of large-scale commercial contracts.