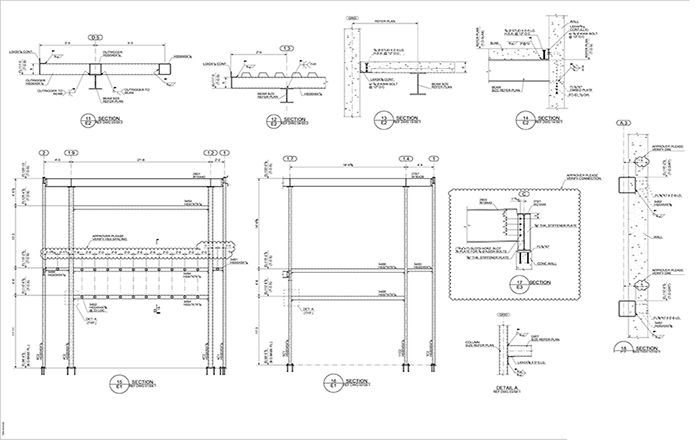

Miscellaneous Metals Shop Drawings

We deliver precise miscellaneous metals shop drawings for stairs, railings, ladders, and specialized supports. Our detailing adheres to AISC/NISD codes. It ensures a perfect fit-up that minimizes field fabrication errors by up to 40%.

DWG, RVT, DXF Support

24/7 Availability

24-48 Hours Turnaround

Types Of Miscellaneous Metals Shop Drawings Services

Miscellaneous metals work rarely fits into neat categories. One project blends many scopes. We prepare detailed shop drawings, like building measurement services, that address fabrication limits, site tolerances, anchor conditions, and coordination gaps before steel ever reaches the field.

Stair & Platform Shop Drawing Services

We detail industrial and architectural stairs, landings, and platforms, including stringer geometry, tread spacing, nosing profiles, and embed locations, ensuring safe egress, clean welds, and predictable installation sequencing.

Railing & Guardrail Detailing Services

Our drawings define post spacing, base plates, infill patterns, handrail heights, and code-required loads. Each connection is resolved, so fabricators avoid guesswork once materials hit the shop floor.

Ladders & Access Systems Shop Drawings

We create ladder drawings showing cage clearances, rung spacing, side rail profiles, and wall offsets. Anchorage points and safety compliance are clearly called out for industrial and commercial environments.

Structural Steel Shop Drawings Services

We produce coordinated shop drawings for beams, columns, clips, and embeds that interface with misc metals. Bolt sizes, weld symbols, and erection notes are resolved to prevent clashes during steel erection.

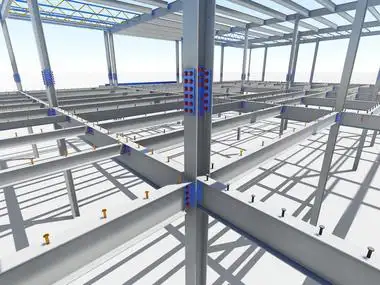

Tekla Steel Detailing Services

Using Tekla, we model complex misc metal assemblies with fabrication-level accuracy. Parts lists, bolt reports, and CNC-ready data are extracted directly from the model to reduce manual errors.

AutoCAD Drawing Services

Our AutoCAD-based shop drawings provide clean layers, consistent dimensioning, and fabrication-ready views. Ideal for projects requiring DWG compatibility with fabricators, engineers, or GC review workflows.

Glazing Support & Misc Interface Drawings

We detail steel supports for glazing systems, including edge angles, embeds, and tolerance gaps. This prevents conflicts between metal fabricators and glazing contractors during installation.

Rebar & Embed Coordination Drawings

We coordinate misc metal embeds with rebar layouts to avoid congestion. Drawings clearly show anchor projection, hook orientation, and pour tolerances, reducing costly field drilling or rework.

Custom Miscellaneous Metal Fabrication Drawings

From canopies to equipment supports, we detail non-standard metal assemblies. Each drawing is built around actual fabrication methods, transport limits, and site constraints, not generic assumptions.

Demising Scenarios & Space Planning Assistance

When deciding to demising or combine tenant suites, we will provide demising scenario plans depicting certain scenarios as they relate to the layout. We will work closely with property managers and leasing teams to find the essential suite configurations within regulatory minimums and the greatest usable space to move forward with.

Stack Plans & Expiration Schedules

We generate full-colour, visually representative stack plans of the tenants stacked on each floor including lease expiration information.

Updates & Revisions on Measurement

Your building is not static, and neither should your measurements be! Whether you’ve undergone a renovation, modified demising walls or simply had tenant turnover, we provide fast turn around measurable drawings and measurement reports.

Outsource Misc Metals Shop Drawings To Us

Outsourcing the miscellaneous metals shop drawings is not about saving a few drafting hours. It is about removing uncertainty. Our team works as an extension of your fabrication or project staff, not a disconnected vendor. We study contract drawings, structural backgrounds, and architectural intent before drawing a single line.

Connections are resolved early. Tolerances are questioned, not assumed. If something cannot be fabricated or installed cleanly, it is flagged before it reaches the shop. We handle revisions, RFIs, and fast-track changes without slowing your schedule.

Time zones work in your favor. While your team rests, drawings move forward. You receive clear, fabrication-ready files that installers can trust, reducing callbacks, site confusion, and last-minute fixes.

Significant Perks Of Misc Metals Shop Drawing

Fewer Field Surprises, Better Site Control

Accurate misc metals shop drawings expose conflicts before fabrication begins, allowing crews to install faster, avoid on-site improvisation, and maintain control over labor hours and safety conditions.

Fabrication That Matches Real-World Conditions

Clear dimensions, connection details, and tolerances help fabricators build ideal components. These actually fit site conditions. As a result, rework, material waste, and trips between shop and field are reduced.

Smoother Coordination Across Trades

Well-prepared miscellaneous metals shop drawings align models with structural steel, concrete, and architectural elements. This prevents trade overlap, schedule clashes, and installation delays that typically surface late in construction.

Programs Used In Misc Metal Shop Drawings

The right software determines how accurately misc metal components translate from concept to fabrication. For instance, when it comes to glazing shop drawing, we rely on proven drafting and modeling platforms. These handle tight tolerances, complex connections, and real-world fabrication constraints.

AutoCAD

AutoCAD is our primary platform for detailed misc metal shop drawings when 2D clarity matters most. We build drawings around real fabrication habits, with readable dimensions, logical callouts, and disciplined layers. Stairs, rails, embeds, and brackets are drawn to reduce interpretation, limit RFIs, and keep installers moving without hesitation.

Tekla Structures

Tekla Structures is used when misc metal assemblies demand full spatial coordination. We model components exactly as they will be fabricated, including welds, bolts, and connection geometry. This approach exposes conflicts early, improves fit-up accuracy, and supports reliable material takeoffs before fabrication begins.

Trusted Clients

9 Perks Of CAD Drafter’s Commercial Misc Metals Shop Drawings

- Fabrication-ready clarity

- Reduced field rework

- Faster approval cycles

- Accurate connection detailing

- Trade coordination support

- Code-compliant layouts

- Predictable installation flow

- Lower material waste

- Reliable revision handling

Here’s What Customers Say About Us

Explore Our Full Range of Drafting and Production Sub-Services

Economical Commercial Misc Metals Shop Drawings

Affordability in the misc metals shop drawings does not come from cutting corners. It comes from experience, process, and discipline. Our pricing stays competitive because our workflows are lean and repeatable, even when project scopes change. We reuse proven detailing standards instead of rebuilding drawings from scratch every time. Our structural steel shop drawings service is a prime example of this practice. It saves hours without sacrificing accuracy.

Time zone coverage also plays a role. Work continues while your internal team is offline, shortening overall production cycles. Fewer delays mean fewer billable revisions. We also focus heavily on getting details right early, which reduces costly redraws later in the project.

Software efficiency matters. Unlike other miscellaneous metals shop drawing companies, we rely on tools that automate reports, part tracking, and revisions, lowering manual drafting time. Most importantly, our drawings reduce fabrication and field errors. When shops build correctly for the first time, the savings extend far beyond drafting fees.

Industries We Serve with Expert Building Measurement Services

Residential Housing

Commercial Builders

Hospitality and Hotels

Mixed-Use Development

Industrial Facilities

Institutional Projects

People Frequently Ask Us These Questions

What exactly is covered in the misc metals shop drawings?

Our miscellaneous metals shop drawings usually show stairs, rails, ladders, embeds, and small steel supports. Dimensions, weld notes, bolt sizes, and materials are included so fabricators are not forced to guess.

Do you follow any codes or just draw what is shown?

We do not trace drawings blindly. Details are checked against AISC, NISD, and project notes. If something feels off, it gets flagged before fabrication starts.

Can you work when drawings are incomplete or changing?

Yes. Many projects arrive half-finished. We mark gaps, ask questions early, and adjust details as answers come in, instead of waiting until everything breaks downstream.

Which file formats do you usually provide?

Most clients receive DWG and PDF files. If needed, we also share DXF or RVT files so drawings fit easily into existing shop or coordination workflows.

How fast can misc metals shop drawings be delivered?

Small scopes often move within a day or two. Larger packages take longer, but progress stays steady once backgrounds, comments, and basic project rules are clear.